Textile Testing Major

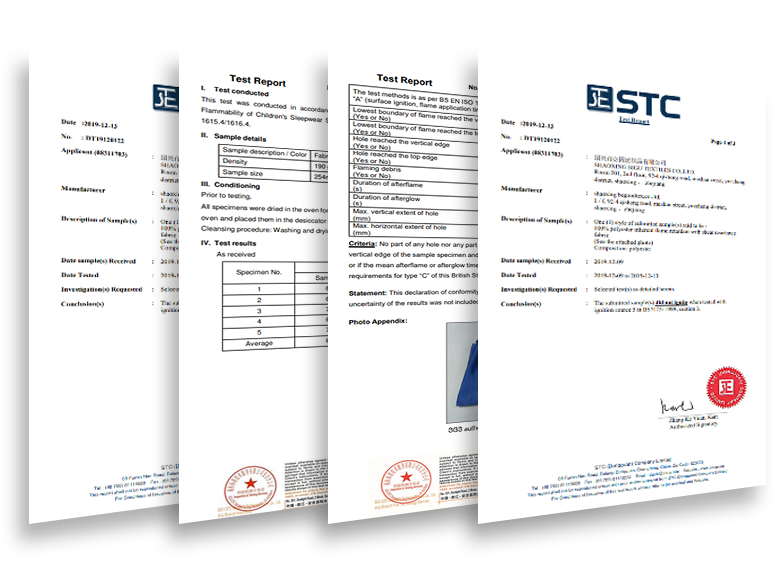

To ensure that our fabrics are safe, durable and most importantly comfortable, experienced inspectors compile a detailed inspection checklist based on your requirements, international regulations, safety standards and our extensive expertise to conduct a thorough inspection of your goods on the spot. The tests we conduct include:

· Properties: Abrasion or Pilling (Martindale, ICI)

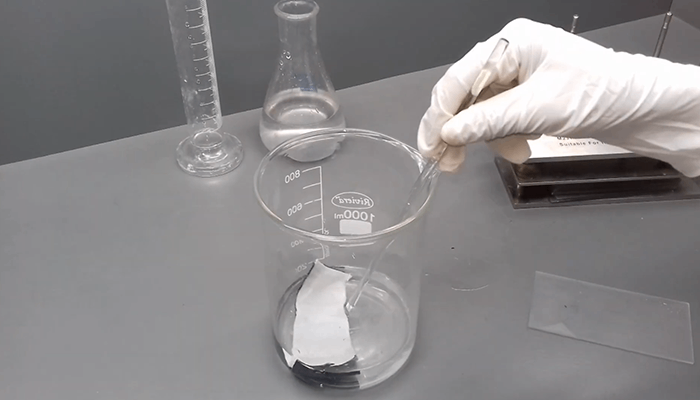

· Weather resistance test: waterproof, windproof, warm, spray test

· Heat resistance and water vapor resistance/permeability

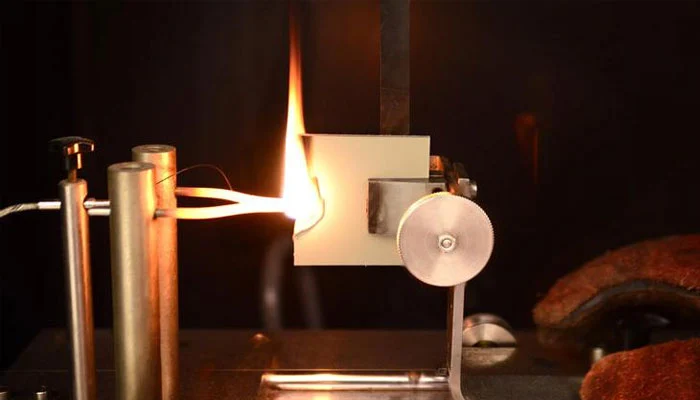

· Burn test (for 100% cotton textiles)

· Seam strength (sewn products)

· Tear Strength and Penetration Resistance

· Tensile Properties