Understanding Waterproof and Oilproof Textiles

Abstract. This article mainly discusses the research and principles of waterproof and oilproof fabrics and introduces the production process and testing performance of mainstream waterproof and oilproof fabrics. BEGOODTEX flame-retardant fabrics also incorporate waterproof and oilproof technology, providing comprehensive fabric protection.

Overview of waterproof and oilproof textiles

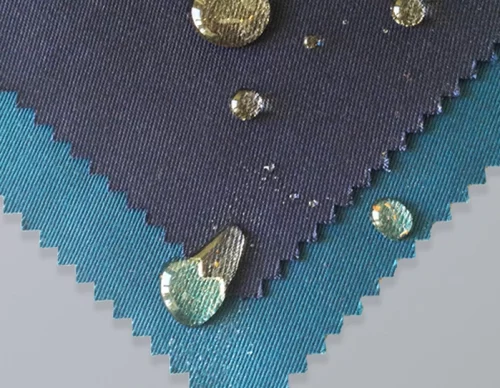

Due to the growing use of textiles in various applications and industries, certain specialized fabrics are no longer content with basic water-resistant treatments. Fabrics featuring both waterproof and oil-resistant qualities are now the focus of advancement due to their ability to repel stains. A fabric’s water repellency indicates how well it can repel water droplets when they come into contact with its surface.

Development overview of waterproof and oilproof finishing agents

Over the past few years, there has been significant growth in using fluorinated substances for waterproof, oil-resistant, and anti-fouling treatments on fabrics. The United States DuPont Company was the first to patent the use of lotion as a finishing agent for making fabrics water- and oil-resistant. In the 1950s, 3M Company from the United States created a fabric treatment that consisted of complex chromium perfluorocarboxylates.

Application of ultrafine fibers in waterproof and oilproof textiles

In the past few years, there has been a rapid development in ultrafine fiber production, which has resulted in the creation of ultra-high-density fabric. This fabric is made using fibers with spaces between them that are smaller than water droplets but larger than water vapor droplets, giving it both waterproof and breathable properties. This high-density fabric feels lightweight, has a soft and smooth texture, and offers good draping qualities owing to its fine structure. Even without any coating or waterproof treatment, it maintains high water resistance, making it a valuable textile product. It is excellent at cleaning up dirt quickly without leaving any residue behind; you can wash it and reuse it too! This cleaning tool is handy for all sorts of tasks, whether in precision machinery workspaces or homes alike.

Application of lotus leaf effect in waterproof and oilproof textiles

The water that falls on the lotus leaves doesn’t seep through them; instead, it gathers into droplets that slide along the leaf’s surface—a phenomenon known as the lotus leaf effect. German scientists have utilized this principle to create surface coatings for buildings that repel water and clean themselves. They’ve also applied the lotus effect to develop clothing with similar properties.

Application of superhydrophobic materials in waterproof and oilproof textiles

Organic compounds and polymers typically have surfaces with energy that resist wetting easily, whereas oxides, sulfides, and inorganic salts exhibit high-energy surfaces that are more prone to being wetted easily. When water’s contact angle exceeds 90° on a surface, it is classified as hydrophobic. If the contact angle surpasses 150°, it is termed a superhydrophobic surface. This type of surface not only repels water effectively but also resists oil, making it a double hydrophobic surface.

Application of petal effect in waterproof and oilproof textiles

It is commonly thought that petals are considered to be a type of leaf accessory, with hairs present in their outer layer too. Certain plant petals exhibit either patterns or inner ridges along the exterior walls of their epidermal cells. Furthermore, the surface of a petal displays a rough texture and possesses water-resistant qualities. In addition, there exists an arrangement of tiny projections across the petal surface, each with numerous small folds at their tips. This characteristic is known as the “effect.” In contrast to the lotus leaf effect is another effect, which exhibits not just impressive hydrophobic properties but also excellent adhesion capabilities.

Application of nanotechnology in waterproof and oilproof textiles

Ultrafine particles, known as nanoparticles, have dimensions in the nanometer scale range, which fall between the size of atoms and conventional particles. Fabrics and textiles are currently a topic of exploration for their waterproof and oil-resistant properties through the application of nano-functional materials. Unveiled to serve various purposes, fabric treatment procedures include the suction method, the immersion rolling method, and the coating method. The dipping technique is predominantly utilized in crafting breathable clothing fabrics suitable for summer and fall wear, such as tops, shirts, and casual attire for both men and women.

Waterproof and oilproof finishing mechanism

Water-repellent treatment mechanism

By adsorbing a layer of substance on the surface of a fabric, the original high-energy surface can be transformed into a low-energy surface, resulting in a fabric with water-repellent properties. The smaller the surface energy, the better the effect. According to the surface energy of different substances, paraffin, siloxane, fluorine-containing compounds, etc. can be selected as fabric water-repellent finishing agents.

Oil-repellent sorting mechanism

The mechanism of oil-repellent finishing is very similar to that of water-repellent finishing, but their requirements are different. After water-repellent treatment, it is required that the fabric can resist the penetration of water under certain pressure, so water cannot wet the fabric, and its contact angle should be greater than 90 °, And oil repellent finishing only requires that the fabric does not spread oil on its surface when it encounters oil, and the contact angle is greater than zero at this time. The interfacial free energy value of oil is much smaller than that of water. Therefore, in order to achieve the goal of oil rejection, a lower gas-solid interfacial tension is required, generally less than the surface tension of the oil.

| Critical surface tension of different polymers | |||

| Polymer | Surface tension (MN/Medium size) | Polymer | Surface tension (MN/Medium size) |

| Paraffin water-repellent finishing products | 29 | Fatty acid | 22 |

| Polytetrafluoroethylene | 18 | Polydichloroethylene | 40 |

| Polytrifluoroethylene | 22 | Polyethylene terephthalate | 43 |

| Polydifluoroethylene | 25 | Polyethylene glycol ester | 46 |

| Polyfluoroethylene | 28 | Cellulose fiber | 72 |

| Polythene | 31 | Polyamide fiber | 46 |

| Polychloroethylene | 31 | Sheep wool | 45 |

| Polystyrene | 33 | Polyvinyl alcohol | Thirty-seven |

| Polyvinyl chloride | 39 | Polyvinyl chloride fibre | Thirty-seven |

| Polymethyl methacrylate | 39 | Silicone water-repellent finishing agent | 26 |

| .Fluorine-containing water-repellent finishing products | Ten | Perfluorinated fatty acids (-CF3.) | 6 |

| The surface tension of the liquid | |||

| Liquid | Surface tension (MN/Medium size) | Liquid | Surface tension (MN/Medium size) |

| Water | 72.8 | Petrol | 22 |

| 80 degreesWater | 62 | Cottonseed oil | 32.4 |

| Rainwater | 53 | Olive oil | 32 |

| Electric engine oil | 30.5 | White mineral oil | 26.0 |

| Peanut oil | 40 | Red wine | 45 |

| Fluorine-containing surfactant solution | 18 | Benzene | 26 |

| Orthoheptane | 20 | Hydrocarbon fluoride | 12 |

| Milk, cocoa | 43 | Paraffin oil | 33 |

Anti-fouling and easy to clean cleaning mechanism

Anti-fouling mechanism.

Oil pollution is a concept that encompasses oil-soluble contaminants and water-soluble pollutants, among others. There are essentially two sources of this pollution: the skin secretions of humans and external intruders. There are typically three ways to imbue fabrics with fouling capabilities: through sizing techniques, film applications, and chemical modification of fibers.

Easy to clean and tidy up mechanism.

Hydrophilic anti-fouling treatment is a method that aims to make cleaning easier by reducing the surface tension of fibers on fabrics and preventing dirt from sticking to them during washing.

Mechanism of ‘Three Defenses’ and ‘Four Defenses’ organization

Research in the field of waterproof and oilproof treatment of textiles is moving towards a method involving the combination of fluorine-based treatment agents with other functional agents, such as wrinkle-resistant finishing and flame-retardant finishing, to create versatile end products with features such as UV protection and antibacterial properties. This trend has given rise to the concept of “three measures” and “four preventive measures” in textile finishing.

Production of waterproof and oilproof Textiles

Waterproof agents commonly utilized in finishing processes primarily consist of paraffin aluminum soap lotion, choline quaternary ammonium salt and chromium stearate complex compounds, hypomethyl melamine derivatives, silicone-based compounds, and organic fluorine compounds. Organic fluorine substances are particularly noted for their water-repellent, oil-repellent, and anti-fouling attributes.

General water-repellent treatment

(1) Temporary waterproof finishing agent

- Aluminum soap and zirconium soap.

Once the fabric is soaked in a soap solution, it is treated with aluminum acetate afterward to create alkaline aluminum acetate and hydroxides of unspecified composition that adhere to the fabric surface. This approach is known as the two-step method.

- Waxes and waxy fabrics

You can apply waxy substances to fabrics either in solid form, heating them until they melt, or as solutions in organic solvents and lotions for treatment purposes.

Paraffin aluminum soap is simple to apply and budget-friendly. It falls under the umbrella of eco-water-repellent substances that are particularly well-suited for treating industrial textiles against water penetration but may not withstand repeated washes effectively.

- Polymer resin based water repellent finishing agent

Its advantage is that it can deposit on fabrics, giving them a high degree of water-repellent properties. The disadvantage is that the processing solution is acidic, which can easily cause brittleness and discoloration of cellulose fiber fabrics during drying and heat treatment, especially for fabrics dyed directly with dyes.

(2) Durable water-repellent finishing agent

To ensure that fabrics possess lasting water-repellent qualities, such as washability and resistance to dry cleaning processes.

(3)Organic silicone oil lotion

Organic silicon compounds exhibit characteristics similar to those of typical polymer compounds. They can enhance the water-resistant properties of a fabric without compromising its breathability and also boost the fabric’s tear resistance, as well as its resistance to corrosion and staining.

Organic fluorine waterproof, oilproof, and anti-fouling finishing

Fluorinated substances not only repel water but also exhibit resistance to different oils, with low surface tension levels.

| Comparison of several finishing agents | ||||||

| .Water-repellent | Water resistance | Reject oil | Durability | Cost | Scope of application | Sort out the product style |

| Paraffins | Same | Different | Different | Low | Cellulose fiber and others | Metal soap feeling, increase in significance |

| Reactive classes such as triazine | Good | Different | Same | Centre | Cellulose fiber | Greasy and thick |

| .Water-repellent | Water resistance | Reject oil | Durability | Cost | Scope of application | Sort out the product style |

| Silicones | Good | Different | Same | Centre | .All kinds of fibers | Too slippery |

| Organic fluorides | Good | Good | Good | Middle to high | .All kinds of fibers | Soft and adjustable to the touch |

Anti-fouling, easy to clean and tidy up

Anti-fouling finishing is usually quite straightforward. You just need to add the additives during the resin-finishing process to get the desired result. These specific additives are known as anti-fouling finishing agents.

Textile finishing primarily involves the application of lasting or moderately lasting anti-fouling agents on fabric surfaces. It can also be categorized based on how the agents are fixed to fibers or fabrics.

- Cross-linked and fixed anti-fouling agents

Cross-linked and durable anti-fouling agents do not adhere directly to fibers or fabrics. They can be combined with resin finishing agents or cross-linkers to bond with fibers through cross-linkage processes, effectively improving the longevity of anti-fouling properties.

- Polymer film-forming material

Polyacrylic acid is used as a finishing agent to prevent fouling and make textiles easier to clean by forming a flexible film on fibers. This creates a smooth surface with good washing resistance due to its affinity for fiber materials.

‘Three Defenses’ and ‘Four Defenses’ treatment

By applying finishing methods to fabrics with organic fluoropolymers, a protective coating is created on the surface that adds a “three-proof” feature to them. The traditional technique of “four-proof” finishing usually requires two baths for the “three-proof” and non-scalding agents, making it time-consuming, complex, and resource-intensive. Advancements in new “three-proof” agents and processes have led to products achieving exceptional “four-proof” outcomes.

Testing of waterproof and oilproof performance of Textiles

Water-repellent performance test

- Water repellent level test

The water resistance of fabrics is typically assessed through a test method that evaluates their ability to repel water effectively, often based on the AATCC 22:2014 protocol.

- Water pressure resistance performance test

Test the sample’s water pressure resistance by connecting a tube-type water pressure gauge to it. Prior to conducting the experiment, make sure the water tank and the testing instrument’s water column are aligned with the sample holder’s plane.

- Testing the washability of fabrics

Clothes should be washed frequently to maintain their freshness and cleanliness. Fabrics treated with fluorine-based chemicals tend to lose their water and oil resistance over time with washing due to an increase in surface energy. This aspect of washability is crucial for evaluating the performance of waterproof and oilproof materials.

- Breathability testing of fabrics

The ability of materials to allow air to pass through is primarily influenced by the openings on the material’s surface, which are shaped by how tightly woven or dense the material is structured. The breathability of textiles can be tested using a fabric breath test tool.

Oil repellent performance test

Use common test solutions made of different hydrocarbons with varying surface tensions on the coating’s surface and observe how the coated fabric reacts to wetting. Determine the oil repellency level based on the numbered standard solution that does not wet the fabric’s surface.

Easy-to-clean performance test

Typical ways of getting ready involve treating and cleaning wastewater, and synthetic wastewater. Popular methods for experiments include droplet staining and friction staining.

Exploring BEGOODTEX Waterproof and Oilproof Textiles

BEGOODTEX waterproof fabric is created by treating a flame-retardant fabric with a process that results in a durable protective film on its surface, making it waterproof and resistant to oil and stains. This is commonly referred to as “three-proof” fabric. The ability to repel water is accomplished by applying a film on the fabric’s surface without blocking its pores. This allows the fabric to be both waterproof and breathable simultaneously, suitable for outdoor tents, curtains, and firefighting protective clothing.