Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

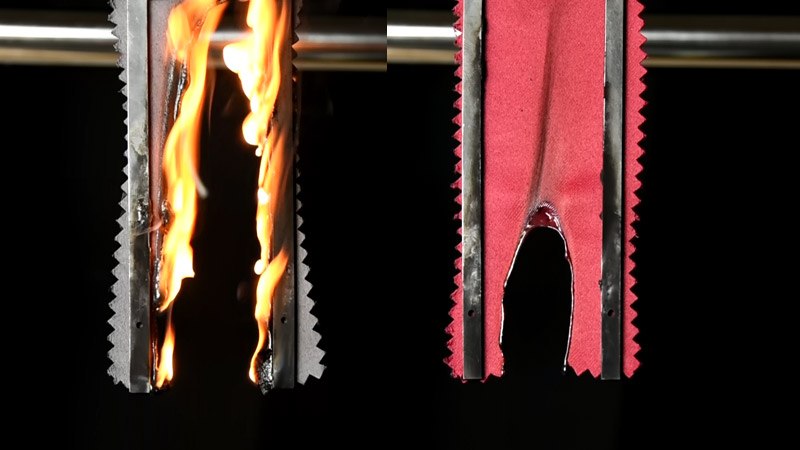

Flame-retardant fabrics or textiles are not fireproof; instead, they are treated with flame-retardant finishes that inhibit the continuous spread of flames or cause charring in the area exposed to fire. These fabrics do not sustain burning after the flame source is removed.

Below are 10 common professional terms used in flame-retardant fabric testing:

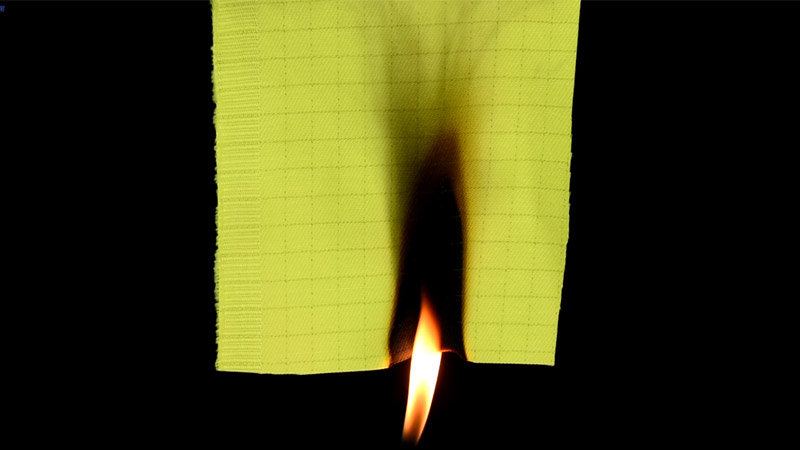

Char length refers to the length of the charred area on the fabric after burning (unit: mm). This indicator is measured through vertical burn testing, where the sample is hung vertically, ignited, and then extinguished before measuring the charred section after cooling. The shorter the char length, the better the fabric’s flame resistance. Standards like NFPA 701 typically require a char length not exceeding 150 mm, with smaller values indicating better performance.

Flame time is the duration (in seconds) during which the fabric continues to burn after the flame source is removed. Vertical or horizontal burn tests record the time the flame persists on the sample. Shorter flame times indicate better flame-retardant performance. High-quality flame-retardant fabrics often exhibit flame times close to 0 seconds, meeting B1 or higher classification standards.

Afterglow time refers to the duration (in seconds) that the smoldering or weak glowing of the fabric persists after the flames are extinguished. This time is recorded during testing after the flame source is removed. Shorter afterglow times indicate stronger anti-smoldering performance. Fabrics meeting safety standards usually have an afterglow time of less than 2 seconds.

LOI is the minimum concentration of oxygen (expressed as a percentage) required to sustain combustion in a controlled environment of oxygen and nitrogen. This is measured using specialized equipment, and higher LOI values indicate better flame-retardant properties. Generally, an LOI > 28% is considered flame-retardant, while < 21% is considered highly flammable.

Dripping behavior assesses whether molten droplets are formed during the burning process and whether these droplets ignite other materials. The test observes whether the fabric produces molten drips during combustion. High-quality flame-retardant fabrics produce no dripping or droplets that do not ignite other objects, meeting B1 or higher flame-retardant standards.

Flame spread rate measures the speed at which flames propagate across the surface of the sample (unit: mm/s). This rate is calculated by recording the time and distance of flame propagation in horizontal or vertical burn tests. Slower flame spread rates indicate better flame-retardant properties. High-grade flame-retardant fabrics often exhibit flame spread rates close to 0.

Smoke density refers to the concentration of smoke produced during fabric combustion, typically measured using light transmittance or optical density. Lower smoke density indicates that less smoke is generated during combustion, implying better safety and environmental performance. Flame-retardant fabrics generally require low smoke density to meet environmental and safety regulations.

Char residue rate is the ratio of the weight of the residue after burning to the original weight of the sample (unit: %). This is measured using a weighing method, and higher residue rates indicate better high-temperature resistance and flame-retardant performance. Flame-retardant textiles generally have a char residue rate of over 30%.

HRR refers to the rate of heat energy released per unit area during combustion (unit: kW/m²). Measured using a cone calorimeter, lower HRR values indicate less heat generated during combustion, signifying better flame-retardant performance. Flame-retardant fabrics typically require an HRR below 50 kW/m².

Flame retardant rating is the classification of a material’s flame resistance according to specific standards, such as China’s B1/B2 levels or the U.S. NFPA 701 standard. Higher ratings indicate better flame-retardant performance, usually requiring the material to meet stringent criteria for multiple indicators such as flame time, afterglow time, and char length.