Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Abstract: Based on the characteristics of poor permeability and flammability of ordinary polyester fabrics, this article will explore the processing technology of polyester fabrics through extensive experiments, and elaborate on the flame retardant mechanism, flame retardant testing methods, and related flame retardant standards.

In recent years, the average annual number of fires is 30000 to 40000, the average annual death toll is 2000 to 3000 people, and the average annual fire losses have reached 200 to 300 million yuan and still show an upward trend. Investigation into fire causes in the US, UK, and Japan shows that more than half of the fires started from textiles. So people across the globe consider it important to prevent textiles from catching fire.

Judging from the rising trend of civil and industrial textile consumption, and the increasing usage of textiles such as indoor decoration, cabin decoration, and bedding, the number of fires caused by textiles is also increasing accordingly. The definition of flame retardant finishing of textiles, flame retardant standards, testing methods, as well as technical indicators for different kinds of textiles, have also been proposed by countries such as Japan, Europe, and America since the 1960s, laying the foundation for the quality control of textile flame retardancy.

BEGOODTEX Aquafyreguad™ flame retardant treatmentconsists of being able to penetrate small molecules of flame retardant materials into large polyester molecules based on a padding method during setting processes at high temperatures. As a result, excellent flame retardancy and novel wash resistances are applied to these fabrics making it very vital in the metallurgy, chemical, and fire protection industry.

The combustion of textiles requires three conditions: heat, air, and combustible material. During the burning process, textiles undergo several stages including heating, melting, pyrolysis, decomposition, oxidation, and ignition.

To enable combustion by synthetic fibers such as polyester, it needs to meet the criteria, which is that: the polymer should degrade to form gaseous combustion products, the heat released by the combustion should be capable of leaving these gaseous combustion products, and that both the gaseous combustion products and the gaseous oxygen should mix and propagate to the ignition sites, and that the burning portion should propagate into the regions where gas oxygen mixtures exist. To mitigate these conditions, flame retardant principles seek to decrease or eliminate the ease of production of the thermal decomposition gases, inhibit key reactions in gas-phase combustion, absorb energy in regions of burning, and either dilute or separate air.

Flame retardancy in materials is often achieved through various mechanisms including gas-phase retardation, condensed-phase retardation, and interruption of heat exchange mechanisms:

1.Gas-phase retardation functions by inhibiting free radicals that promote combustion chain growth.

2.Condensed-phase retardation delays or prevents polymer thermal decomposition within the solid phase.

3.Interruption of heat exchange mechanisms involves removing part of the heat generated by polymer combustion.

Polyester fiber fabrics can undergo flame-retardant finishing through three main methods:

1.Designing flame retardants with an adsorption structure similar to disperse dyes and applying them using a finishing-dyeing one-bath process.

2.Using thermos methods to fix flame retardants with high affinity for polyester fibers onto them. This method has limited suitable flame retardants but offers minimal impact on hand feel and good washing fastness.

3.Employing leachable flame retardants which are easy to use and effective but not wash-resistant. They are suitable for natural and chemical fiber fabrics as well as paper used in interior decoration materials like those found in hotels and automobiles.

Non-durable treatments involve processes such as:

Utilizing BEGOODTEX®’s Aquafyreguad™ can achieve national flame-retardant standard B2 level indicators while being washable over 50 times.

Since as early as 1953 the United States has enacted legislation such as the Flammable Fabrics Act(FFA), amending the act in 1954, and again in 1967. The law was passed by the U.S. Congress and implemented by the U.S. Consumer Product Safety Commission (CPSC). This bill predominantly contains the combustion technical specifications:

In Canada, the legislation on the flame retardancy of textiles and clothing is contained in the Dangerous Goods Regulations and Rules. In Canada, the legislative assembly of the province enacts so-called “Dangerous Goods Regulations”, and by maintaining the ability to be relevant to strictly abide by an ever-expanding number of regulations including “Dangerous Goods (Children’s Pajamas) Regulations”, “Dangerous Goods (Carpets) Regulations”, “Dangerous Goods (Tents) Regulations”, “Dangerous Goods (Toys) Regulations”, “Dangerous Goods (Mattresses) Regulations”, etc, and is the governing body last decreed of this naturally indirect path to complication and bureaucracy.

| Classification | Stipulate standards | Experimental method | Formulation unit | Date of implementation or revision (year) |

| Curtains, tents, engineering covers | Article 4 (3) of the Enforcement Order of the Fire Law | 45° tilt method, washing, dry cleaning | Department of Defense | 1968 |

| Notice No. 11 of the Fire Department | 1973 | |||

| Sleeping equipment, pajamas | Fire Department No. 65 | 45° tilt method wash resistance, oral toxicity, skin allergy | Fire Department | 1974 |

| Household textiles (curtains, sheets) | Quality representation of household products | JIS L 1091A, B | 1972 | |

| Wall cloth | Notice No. 1271 and No. 3415 of the Building Standards Law | Smoke, heat, combustion gas toxicity | Department of Construction | 1971 |

| Interior decorative fabric | Article 1 of the Annex to the Rules for the Implementation of the Aviation Law | Horizontal method, vertical method | Department of Transport, Aviation Bureau | 1969 |

| Ferry and other ship interior decorative fabrics | Ship No. 367, No. 481 | JIS L 1091A, B | Department of Transport, Aviation Bureau | 1971 |

| Decorative fabric in the car | JIS D 1201. | FMVSS302. | Industry meeting | 1973 |

| Decorative fabrics and sleeping utensils in trains and buses | Administrative Instruction No. 81 of the Railway Supervision Bureau | JIS Z 2150, 45° tilt method | Department of Transport, Railway Bureau | 1969 |

| Toys | Toy burning standards | Horizontal method | Toy Association | 1973 |

| Military textiles | Specifications of the Department of Defense | JIS L 1091B method | Department of Defense |

Regulatory Framework: Each State in Australia set out its own flame retardant technology requirement regulating flame retardant performance and Testing Methods of Children’s Nightwear sizes 00-14 Children’s evening wear: children’s sleepwear and camp nightgowns, yukata, and baby sleeping bags shall be tested in accordance with the methods in AS/NZS 1249 and shall comply with the safety requirements for children’s evening wear in this standard.

Children’s evening wear (for children aged 3 months to 13 years) must pass the performance burn test in accordance with British standard BS5722 and adult evening wear must carry a permanent label indicating if the garment meets the combustion standard. Evening wear that may have been treated with flame retardants must be labeled how it can be cleaned or what kind of detergent can be used. Prior to combustibility testing, the washing procedure in accordance with BS5651 needs to be undertaken.

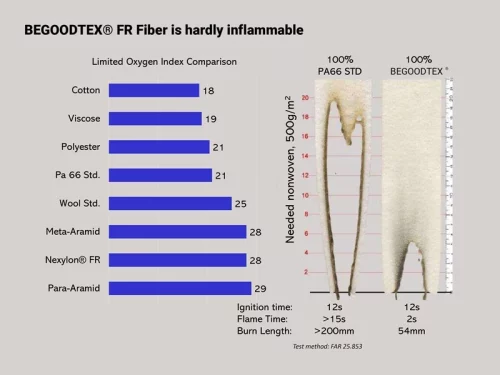

The minimum O2 concentration that is needed that will still sustain the candle like combustion of a fabric is the Oxygen limit index method, in which it is burned in a mixture of O2 and N2 gases. The greater the limit of oxygen index, the better the flame retardancy of the product. On the contrary, if the oxygen limit index is lower, the flame retardant effect is likely to be poor or non-f flame retardant.

In the vertical test, a piece of fabric material placed vertically is exposed to an open flame, whereafter the after-flame time, char length, etc. are measured. It helps evaluate the time required for the ignition of a fabric and the distance traveled by the flames on its surface, which provides information regarding the fabric for its various applications. Vertical combustion is one of the most complete flame retardant performance testing methods at home and abroad and has been normative and guide in various industries, such as China GB8965 98 “Flame retardant protective clothing” GB17591 1996 “Flame retardant weaved fabrics” and so on.

Samples are set at a 45 ° angle and ignited for 1 s, under the aforementioned conditions. Fabric combustion intensity is assessed by the time needed for the sample to burn flames upward a given distance. This basically describes the flame retardant of the fabric, and it is measured based on the test data such as time of continued smoldering, area of damage, and length of damage.

The spread distance of the flame on the sample and time to this distance corresponds to the spread distance of the flame and its time to this distance under the condition in the horizontal direction for 15 seconds when igniting the cloth sample, then the flame spread state track as well as flame retardant function of the fabric is measured in order of its flame spread time and flame spread rate.

BEGOODTEX flame retardant polyesterproducts are manufactured to adhere to compliance with international standards, yet long-lasting protection throughout wash cycles.

By employing flame retardant tests such as LOI and vertical flammability testing, our products are proven to have fire-reducing capabilities over a wide range of applications. BEGOODTEX has continued to innovate in brand textile safety technology, providing multi-functional flame retardant fabric complimenting with the GB8965-1998 national standards in China and NFPA in the USA.