Contattaci

Grazie per averci contattato! teldi più sulle tue esigenze: il nostro team di esperti ti risponderà entro 24 ore.

Contattaci

Grazie per averci contattato! teldi più sulle tue esigenze: il nostro team di esperti ti risponderà entro 24 ore.

Astratto: In questo articolo vengono introdotti principalmente l'importanza e i metodi di produzione dei tessuti e dei prodotti tessili antibatterici e deodoranti, la classificazione dei diversi tessuti antibatterici e deodoranti, nonché i metodi e gli standard di prova.

I microbi svolgono un ruolo importante nel mantenimento dell'equilibrio naturale degli ecosistemi, grazie alle loro piccole dimensioni e alla loro struttura semplice come tratti distintivi. Sono generalmente classificati in tre gruppi in base alle loro caratteristiche: microrganismi non cellulari con caratteristiche procariotiche e microrganismi con caratteristiche eucariotiche. La maggior parte dei microrganismi è innocua o addirittura benefica per l'uomo; tuttavia, alcuni di essi possono rappresentare un rischio per la salute, sia per l'uomo che per altri esseri viventi. Questi microrganismi nocivi che possono causare malattie sono noti come agenti patogeni.

I batteri sono la tipologia di microrganismi più diffusa e diversificata, classificati principalmente in cocchi, bacilli e spirochete in base alla loro morfologia. I batteri sono ampiamente presenti in natura, alcuni dei quali sono strettamente correlati alla salute umana. Ad esempio, lo Staphylococcus aureus può causare infezioni cutanee e altri problemi di salute, mentre i batteri lattici sono una componente importante dei probiotici in grado di regolare il microbiota intestinale.

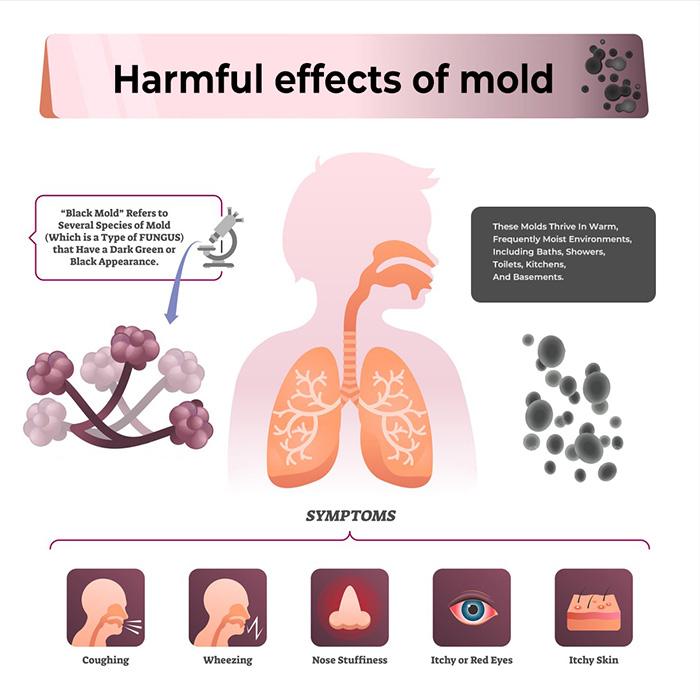

I due gruppi principali di funghi sono lieviti e muffe, che svolgono un ruolo in vari settori industriali, come la produzione alimentare, dove il lievito viene utilizzato per la fermentazione e nella produzione del vino, mentre i funghi contribuiscono alla scomposizione dei materiali organici e ai processi di produzione di antibiotici. Nonostante il loro ruolo in determinati settori industriali e sistemi ecologici, alcuni tipi di funghi, come il fungo bianco, possono causare malattie come il piede d'atleta, con effetti negativi sulla salute umana.

I microrganismi non cellulari come i virus dipendono dalle cellule ospiti per sopravvivere. Possono causare malattie gravi come l'influenza e il COVID-19. Oltre ai virus, anche protozoi e cianobatteri svolgono un ruolo negli ecosistemi e sono utilizzati in varie applicazioni industriali.

I tessuti svolgono un ruolo importante nella nostra vita quotidiana perché entrano in contatto diretto con la nostra pelle; per questo motivo è fondamentale mantenerli puliti, sia per motivi igienici che per il benessere generale.

Materiali naturali come cotone e lana tendono ad attrarre microrganismi a causa della loro capacità di assorbire l'umidità, nota come igroscopicità. In aree con alti livelli di umidità, microrganismi come Aspergillus niger e Penicillium possono moltiplicarsi rapidamente sulle fibre di cotone, causando la formazione di muffe che si manifestano con una colorazione giallastra sulla superficie delle fibre, un odore sgradevole e una diminuzione della resistenza.

Sebbene le fibre sintetiche siano prive di elementi nella loro composizione, gli oli e gli additivi applicati durante la produzione potrebbero offrire i nutrienti essenziali per la proliferazione dei batteri. Ad esempio, i composti lipidici che aderiscono alle fibre di poliestere possono favorire la crescita di Escherichia coli, causando lo scolorimento del tessuto e il degrado delle sue prestazioni nel tempo.

Gli esseri umani producono naturalmente delle secrezioni. Il sudore funge da nutrimento per i microrganismi presenti nel corpo. Quando questi microrganismi scompongono i componenti del sudore, rilasciano sostanze, come acidi grassi insaturi e ammoniaca, che possono causare odori sgradevoli. Questo non solo rende scomodo indossare abiti, ma può anche potenzialmente irritare la pelle.

In sostanza, la creazione di tessuti con proprietà deodoranti si rivela una valida soluzione ai problemi sopra menzionati. Questo sviluppo contribuisce ad aumentare la soddisfazione degli utenti e a promuovere il benessere pubblico.

Le origini dei tessuti antimicrobici risalgono all'antico Egitto, circa 4000 anni fa, quando le persone utilizzavano erbe e minerali per preservare e migliorare la longevità dei tessuti. Nel corso del secolo, i progressi nella tecnologia chimica portarono al perfezionamento delle tecniche di finitura antibatterica. Durante la Seconda Guerra Mondiale, la tecnologia antimicrobica svolse un ruolo importante nel trattamento delle uniformi militari per preservare l'igiene dei soldati in condizioni difficili.

Inizialmente antibatterici e antiodore, i tessuti si basavano principalmente su trattamenti come la nebulizzazione o l'applicazione di sostanze sulla superficie. Sebbene questo metodo sia semplice, la sua efficacia antibatterica tende a diminuire nel tempo, in particolare dopo ripetuti lavaggi.

Negli anni '90, i ricercatori hanno iniziato a studiare l'integrazione di elementi direttamente nelle fibre per creare fibre con proprietà antibatteriche durature. Questo approccio migliora notevolmente la resistenza e la sicurezza dei tessuti.

La crescente consapevolezza della salvaguardia dell'ambiente ha suscitato interesse nell'esplorazione di materiali antibatterici naturali come il chitosano e gli estratti vegetali, per la creazione di tessuti antibatterici ecocompatibili. In futuro, si prevede che i tessuti antibatterici e resistenti agli odori evolveranno verso opzioni più versatili per soddisfare le crescenti esigenze del mercato.

Gli agenti antibatterici svolgono un ruolo nel conferire ai tessuti proprietà antibatteriche e i tipi e le caratteristiche specifiche di questi agenti hanno un impatto diretto sull'efficacia delle proprietà antibatteriche dei tessuti. La selezione e l'applicazione appropriate di questi agenti possono migliorare notevolmente l'igiene e la durata dei tessuti.

La scelta dei farmaci antibatterici implica la valutazione attenta di diversi fattori, quali:

I diversi tipi di agenti di finitura sono classificati principalmente come composti inorganici, sostanze organiche o prodotti naturali, a seconda della loro composizione chimica e origine, ognuno dei quali presenta benefici distinti e usi specifici.

Gli ioni metallici, come quelli presenti negli agenti antibatterici inorganici, si attaccano alle pareti delle cellule microbiche e ne alterano la struttura, prevenendo efficacemente la crescita batterica su diversi ceppi con effetti duraturi. Alcuni materiali, come il nanoargento, sono ampiamente riconosciuti per la loro efficacia e sicurezza nelle applicazioni tessili, nonostante il loro prezzo rispetto ad altre opzioni disponibili oggi.

Alcune sostanze naturali con proprietà antibatteriche sono i sali di ammonio quaternario e i composti di guanidina, tra gli altri, come i fenoli. Queste sostanze agiscono penetrando nelle membrane cellulari o bloccando la funzione enzimatica per uccidere efficacemente i batteri. Ad esempio, i composti di ammonio quaternario possono distruggere i batteri attaccandosi alle loro pareti cellulari e modificando il funzionamento della membrana. Rispetto agli agenti antibatterici, quelli organici sono più facili da personalizzare, ma potrebbero non durare altrettanto a lungo.

Estratti vegetali come l'olio di tea tree e l'artemisia, e sostanze di origine animale come il chitosano e il lisozima, sono agenti antibatterici dotati di potenti proprietà antibatteriche e rispettosi dell'ambiente grazie alla loro biodegradabilità, un aspetto promettente per il futuro della produzione tessile incentrata sulla sostenibilità e sull'ecocompatibilità. La capacità dei chitosani di interagire con le membrane cellulari attraverso la loro carica positiva ne altera la struttura, una caratteristica che ne ha favorito l'ampia applicazione nei tessuti medicali.

Gli agenti di finitura antimicrobici agiscono prevenendo o eliminando i microrganismi mediante metodi di azione.

Effetto fisico: Modificare la struttura della superficie del tessuto, ad esempio creando un nanofilm, può aiutare a impedire ai microbi di attaccarsi ad esso.

Azione chimica: L'azione chimica comporta l'uccisione dei microrganismi mediante il rilascio di sostanze attive, come ioni metallici o radicali liberi.

Azione biologica: Sfruttando la risposta di sostanze antibatteriche e microrganismi, come l'interferenza con i sistemi enzimatici, per bloccarne la moltiplicazione e lo sviluppo.

Nel corso degli anni si sono verificati continui miglioramenti e progressi nel processo di produzione delle fibre antibatteriche attraverso l'incorporazione di elementi antibatterici all'interno delle fibre stesse, per prolungare l'efficacia antibatterica e la durata dei tessuti, migliorandone al contempo l'ecocompatibilità e la praticità.

La chitina e il chitosano sono composti derivati dai gusci di gamberetti e granchi, noti per le loro forti proprietà antibatteriche e per la loro compatibilità con gli organismi viventi.

Processo di produzione

La creazione di fibre di chitina e chitosano avviene tramite la tecnologia della filatura. Il processo fondamentale consiste nei seguenti passaggi:

Esempi di applicazione

Le fibre di chitina trovano applicazione in campo medico, ad esempio nelle medicazioni per ferite e nelle suture chirurgiche, e vengono utilizzate anche nell'abbigliamento funzionale progettato per le sue proprietà antibatteriche e traspiranti.

Le fibre antibatteriche miste vengono create combinando agenti batterici con polimeri di matrice attraverso un processo di filatura, che aiuta a mantenere un equilibrio tra efficacia antibatterica e resistenza meccanica, rendendola una tecnica fondamentale per la produzione di fibre funzionali.

Caratteristiche del processo

Vantaggi

I tessuti misti sono resistenti e duraturi, pur mantenendo efficaci proprietà antibatteriche anche dopo numerosi lavaggi, in contesti di lavaggio ad alta frequenza, e consentono processi di produzione efficienti su larga scala.

La creazione dei tessuti prevede l'impiego di diverse tecniche tecnologiche per conferire ai materiali tessili efficaci qualità antibatteriche attraverso specifici metodi di lavorazione e trattamento che possono variare in base alle caratteristiche del prodotto e agli scenari di utilizzo.

L'aggiunta di proprietà ai tessuti avviene solitamente dopo la fase di lavorazione iniziale, attraverso metodi come l'impregnazione o il rivestimento.

La tecnica di immersione prevede l'immersione del materiale in una soluzione per la finitura antibatterica, per rivestire la superficie della fibra con l'agente antibatterico prima di procedere con i trattamenti di asciugatura e polimerizzazione: un processo semplice applicabile a diversi tipi di tessuto.

Il processo prevede la miscelazione di sostanze con materiali di rivestimento e la loro applicazione uniforme sulle superfici dei tessuti per creare uno strato protettivo che resista efficacemente alla crescita dei batteri e duri a lungo; tuttavia, potrebbe influire leggermente sulla consistenza e sulla traspirabilità dei tessuti.

Il processo di tintura a tampone prevede l'applicazione continua di sostanze sulle superfici dei tessuti, un processo che si adatta perfettamente alla produzione industriale di massa. Si dimostra efficace nell'aumentare i ritmi di produzione e trova ampie applicazioni nel trattamento antibatterico di articoli tessili per la casa, come lenzuola e tende.

Ad esempio, con un agente di finitura antibatterico chiamato DC 570,0, si fissano saldamente i componenti antibatterici attivi alle superfici dei tessuti tramite reazioni chimiche e si dimostra altamente resistente ai lavaggi, offrendo al contempo un'ampia gamma di benefici antibatterici. Inoltre, studi indicano che l'efficacia antibatterica di BEGOODTEX tessuto ignifugo permanenterimane superiore al 90% dopo 50 cicli di lavaggio.

I deodoranti tessili eliminano gli odori dai tessuti attraverso processi come metodi di trattamento e assorbimento o decomposizione delle particelle di odore presenti nel materiale stesso. Con il continuo aumento del desiderio di una migliore qualità della vita tra i consumatori a livello globale, si registra un corrispondente aumento del mercato dei prodotti tessili progettati per combattere i cattivi odori.

I deodoranti trasformano molecole come l'ammoniaca e l'idrogeno solforato in sostanze poco o per nulla profumate mediante adsorbimento chimico o reazioni catalitiche. Il carbone attivo è un esempio di materiale in grado di assorbire molecole grazie alla sua natura porosa; i catalizzatori a base di ossidi metallici scompongono le molecole odorose attraverso reazioni redox.

La fibra deodorante è un tipo di fibra prodotta incorporando componenti deodoranti, come polvere di carbone attivo e particelle di ossido metallico, nel processo di produzione della fibra stessa. Questa fibra unica non solo intrappola gli odori sgradevoli, ma presenta anche un'eccezionale durata e caratteristiche ecocompatibili.

Flusso di processo:

La deodorizzazione dei tessuti viene effettuata principalmente utilizzando tecniche come il rivestimento del tessuto con agenti o l'immersione e la spruzzatura con deodoranti per migliorare il controllo degli odori nei tessuti di uso quotidiano come abbigliamento sportivo e biancheria per la casa.

La valutazione dell'efficacia della deodorizzazione comporta in genere il monitoraggio delle alterazioni nelle concentrazioni di composti organici (VOC) e l'esecuzione di valutazioni sensoriali per misurare efficacemente i cambiamenti di intensità dell'odore nei tessuti.

BEGOODTEX utilizza tecnologia di test avanzataTestare l'efficacia dei tessuti è fondamentale per valutarne l'impatto pratico e solitamente prevede analisi qualitative e quantitative, come approcci comuni.

Valutare l'efficacia delle proprietà misurando la dimensione della zona in cui la crescita batterica è inibita utilizzando la tecnica di diffusione in agar.

Metodo per il conteggio delle colonie; Stimare l'efficacia monitorando le variazioni nella quantità di microrganismi presenti nel campione.

In linea con le linee guida e le situazioni di utilizzo nel mondo reale, i ceppi batterici comunemente utilizzati a scopo di test sono i seguenti;

Valutare l'efficacia di un prodotto antibatterico implica in genere l'analisi di fattori quali il suo tasso antibatterico e l'entità della zona di inibizione che crea sulle superfici su cui viene applicato nel tempo. Inoltre, testare la facilità con cui i tessuti mantengono le loro proprietà dopo il lavaggio è un aspetto cruciale per determinare l'impatto duraturo del trattamento antibatterico.

Standard internazionali:

Attualmente, nel settore tessile, i test sull'efficacia dei tessuti si basano in larga misura su diversi standard internazionali consolidati.

Queste linee guida offrono metodi di prova consolidati nel settore per garantire la coerenza e l'affidabilità delle prestazioni del prodotto.

BEGOODTEX offerte antibatterico ad alte prestazioni Fritardante di zoppia tessutiLe nostre innovative soluzioni tessili sono progettate per inibire la proliferazione di batteri e funghi, garantendo un elevato livello di igiene e sicurezza sanitaria. Il tessuto antibatterico e antimuffa fornito da BEGOODTEX mantiene un tasso di soppressione superiore al 90% anche dopo 50 lavaggi, a testimonianza della durata e dell'efficacia del trattamento applicato al tessuto.