Tessuto ignifugo Begoodtex®

Il tessuto realizzato con fibre ignifughe permanenti riduce l'infiammabilità. Mantiene le prestazioni ignifughe e ritarda la velocità di combustione.

Che cosa è un tessuto ignifugo?

Tessuto ignifugo Si riferisce a un tipo di tessuto realizzato con fibre ignifughe o trattato con sostanze chimiche ignifughe per ridurne l'infiammabilità in vari gradi. Ritarda significativamente la velocità di combustione e può autoestinguersi rapidamente dopo aver abbandonato la fonte dell'incendio, rilasciando una quantità minima di fumo tossico. I tessuti ignifughi possono anche avere funzioni aggiuntive, come antistaticità, resistenza all'olio, resistenza all'acqua e resistenza ai raggi UV. Quando un tessuto ha due o più di queste funzioni, è definito tessuto ignifugo multifunzionale.

I vantaggi del tessuto ignifugo BEGOODTEX includono:

- Buone prestazioni di sicurezza: la fibra non si scioglie ed emette poco fumo se esposta al fuoco.

- Effetto ritardante di fiamma intrinseco (permanente): il lavaggio e l'attrito non influiscono sulle prestazioni ritardanti di fiamma.

- La tutela dell'ambiente è garantita dall'utilizzo di fibre naturali come materiali di supporto, che possono degradarsi naturalmente, soddisfacendo i requisiti ambientali.

- Eccellenti proprietà ignifughe e resistenti al fuoco, che dimostrano buone prestazioni nella prevenzione della propagazione delle fiamme, nel rilascio di fumo, nella resistenza alla fusione e nella durata.

- Un buon isolamento termico e proprietà antistatiche garantiscono una protezione termica completa.

- Caratteristiche delle fibre naturali: il tessuto possiede le proprietà assorbenti e traspiranti delle fibre naturali, oltre a una consistenza morbida, confortevole e dai colori vivaci.

Classificazione dei tessuti ignifughi in base ai metodi di lavorazione dei materiali:

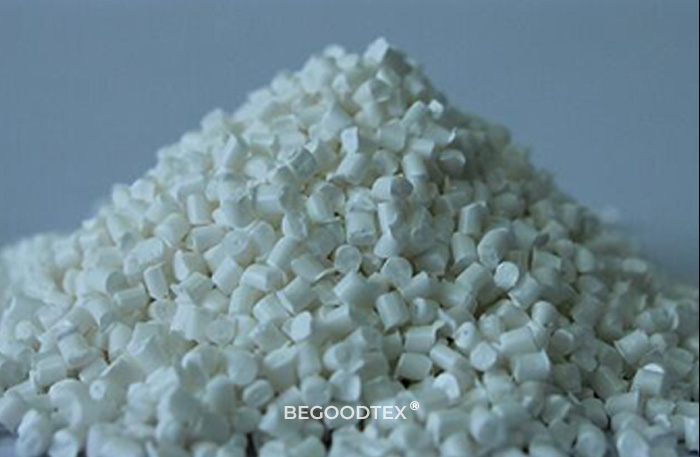

1. Fibra ignifuga (tessuto ignifugo intrinseco)

Una fibra mista si ottiene copolimerizzando monomeri ignifughi con polimeri ad alto peso molecolare o aggiungendo agenti ignifughi ai polimeri. La fibra mista viene quindi tessuta in un tessuto ignifugo. Le fibre ignifughe vengono incorporate con ritardanti di fiamma durante il processo di stiratura, fuse con le fibre e mantengono il loro effetto ignifugo indipendentemente dal numero di lavaggi. Le fibre sintetiche possono essere filate e tessute utilizzando fibre ignifughe, oppure è possibile applicare ai tessuti agenti di finissaggio ignifughi per ottenere l'ignifugazione. I tessuti in fibre naturali possono ottenere l'ignifugazione solo attraverso un finissaggio ignifugo.

2. Trattato ignifugo (FRT)

Il processo prevede il rivestimento con ritardante di fiamma, l'immersione nel ritardante di fiamma e la spruzzatura con ritardante di fiamma. Ad esempio, i rilasci di sabbia generalmente utilizzano un rivestimento di ritardante di fiamma per evitare che la superficie del tessuto venga danneggiata dal ritardante di fiamma, che potrebbe causare alterazioni di colore e consistenza. Le tende sono per lo più trattate con ritardante di fiamma per immersione, che richiede un buon drappeggio. Le zanzariere per finestre sono trattate con ritardante di fiamma a spruzzo, che altera minimamente le caratteristiche originali del tessuto.

Classificazione in base alla resistenza al lavaggio dell'effetto ritardante di fiamma

- 1. I tessuti ignifughi temporanei sono tessuti ignifughi che perdono le loro proprietà ignifughe dopo il lavaggio. Sono utilizzati principalmente per tessuti che non necessitano di lavaggio durante l'uso, come i tessuti per tappezzeria e le coperte elettriche.

- 2. Tessuti ignifughi semi-durevoli: questi tessuti hanno un effetto ignifugo e possono resistere a 1-15 lavaggi delicati. Sono comunemente utilizzati per articoli come tende, sipari per palcoscenici, ecc.

- 3. Tessuti ignifughi durevoli: gli effetti ignifughi possono resistere a 50-200 lavaggi con sapone. I tessuti ignifughi hanno una vasta gamma di applicazioni, tra cui abbigliamento e biancheria da letto.

- 4. I tessuti ignifughi intrinseci (permanenti) sono realizzati con fibre ignifughe e hanno effetti ignifughi intrinseci (permanenti). Le fibre ignifughe vengono incorporate durante il processo di stiratura, fuse con le fibre e mantengono il loro effetto ignifugo anche dopo il lavaggio.

In generale, alcuni tessuti decorativi e prodotti in cotone che vengono lavati raramente possono essere sottoposti a un trattamento ignifugo temporaneo; i tessuti decorativi per interni come tende, materassi e coperte elettriche richiedono un trattamento ignifugo semi-resistente; e indumenti, lenzuola, federe, abiti da lavoro, ecc. richiedono un trattamento ignifugo durevole. Naturalmente, con il miglioramento della durata del trattamento, aumenta anche il costo.

Classificazione in base alle caratteristiche di combustione delle fibre.

I tessuti ignifughi sono classificati in base alle caratteristiche di combustione delle fibre. A causa delle diverse strutture chimiche dei vari materiali fibrosi, anche le loro prestazioni di combustione variano. In base alla facilità di accensione, alla velocità di combustione, alle proprietà autoestinguenti e ad altre caratteristiche di combustione delle fibre quando vengono bruciate, le fibre possono essere classificate qualitativamente in fibre ignifughe e fibre non ignifughe. Le fibre ignifughe includono fibre non infiammabili e fibre difficili da bruciare, mentre le fibre non ignifughe includono fibre infiammabili e fibre facilmente infiammabili.

Classificazione per contenuto di composizione

In base alla composizione dei materiali, i tessuti ignifughi vengono classificati in diverse categorie, come tessuti ignifughi in poliestere aromatico, tessuti ignifughi ecologici, tessuti ignifughi interamente in cotone, tessuti ignifughi in CVC e tessuti ignifughi in cotone nitrilico.

Metodi di produzione di fibre ignifughe.

Poliestere ignifugo

Il poliestere è una fibra termoplastica combustibile che si ammorbidisce, fonde, si restringe e forma goccioline che si allontanano dalla fonte di calore quando esposta al fuoco. Prima di raggiungere il punto di accensione della fibra, la maggior parte del calore viene consumata nel processo di fusione. Si può considerare che più bassi sono il punto di rammollimento e il punto di fusione della fibra, e maggiore è la differenza tra il punto di fusione e il punto di accensione, più difficile è l'accensione. A causa del basso calore di combustione del poliestere, la sua velocità di combustione è lenta. La quantità di fumo prodotta dalla combustione del poliestere è moderata e la tossicità del fumo è bassa.

Cotone ignifugo

Il tessuto ignifugo in cotone si ottiene applicando un trattamento ignifugo al tessuto di cotone. Il processo di trattamento ignifugo include principalmente PROBAN, PYROAVTEX, ecc. Il tessuto ignifugo in cotone presenta buone prestazioni ignifughe e ignifughe senza compromettere il comfort originale del tessuto. Mantiene le caratteristiche della fibra di cotone, come traspirabilità, comfort e morbidezza al tatto.

Il finissaggio ignifugo temporaneo o semi-durevole dei tessuti di cotone si ottiene principalmente impregnando il tessuto con sostanze come diidrogenofosfato di ammonio, diidrogenofosfato diammonio, urea, borace, acido borico e polifosfato di ammonio mediante essiccazione per immersione o impregnazione, seguita da cottura. Alcuni ritardanti di fiamma possono presentare fenomeni di assorbimento di umidità o cristallizzazione durante lo stoccaggio e l'uso del tessuto, richiedendo quindi un'attenta selezione. Il tipico processo di finissaggio ignifugo durevole è il finissaggio Proban. Il finissaggio Proban è un brevetto della britannica Albright and Wilson Company, leader mondiale nel settore dei ritardanti di fiamma per tessuti a base di fosforo. I principali prodotti ritardanti di fiamma sono Proban e Amgard.

Lo standard dei tessuti ignifughi BEGOODTEX

|

stati Uniti |

NFPA 701, NFPA 260, CAL TB 117, CA Title 19, CFR 1615/1616, FMVSS 302 |

|

Canada |

CAN/ULC-S109-14 |

|

Europa |

EN13501-1, EN13773 Class1 |

|

Germania |

DIN 4102-B1, DIN EN 1021 Teil 1, DIN EN 1021 Teil 2 |

|

Francia |

NF P92-503-M1 |

|

Regno Unito |

BS 5815, BS 5852 Crib 5, BS 5867 Type C, BS 7175 Source 7 |

|

Italia |

Uni 9177 |

|

Giappone |

JIS L1091 |

|

Russia |

GOST R 50810-95 |

|

Imo |

IMO Res.A.471(XII), IMO Res.A.652(16) |

Metodi di prova dei ritardanti di fiamma

1. Metodi di prova di base

I cosiddetti metodi di prova di base si riferiscono alle tecniche utilizzate per misurare l'ampiezza della combustione (area carbonizzata e lunghezza del danno), il tempo di combustione continua e il tempo di post-incandescenza dei materiali. Un campione di dimensioni specifiche viene acceso con una fonte di accensione designata per 12 secondi in una camera di combustione specifica. Dopo aver rimosso la fonte di accensione, vengono misurati il tempo di combustione continua e il tempo di post-incandescenza del campione. Una volta cessata la post-incandescenza, la lunghezza del danno (lunghezza del carattere) viene misurata secondo il metodo prescritto. In base alla posizione relativa del campione e della fiamma, i metodi possono essere classificati come metodi verticali, inclinati e orizzontali. In generale, il metodo verticale è più rigoroso rispetto ad altri metodi ed è adatto per tessuti decorativi, tende, materiali per la decorazione degli interni di aeromobili, ecc. Il metodo inclinato è adatto ai tessuti utilizzati per la decorazione degli interni di aeromobili, mentre il metodo orizzontale è più appropriato per i tessuti comuni utilizzati nell'abbigliamento. Lo standard cinese GB/T 5455-2014 è applicabile per testare vari tessuti.

2. Test dell'indice limite di ossigeno

Il test viene condotto utilizzando un misuratore dell'indice di ossigeno. Un campione di dimensioni specifiche viene inserito nel tubo di combustione del portacampioni e il rapporto tra ossigeno e azoto viene regolato. Il campione viene acceso utilizzando un accenditore specifico e brucia per un periodo di tempo prestabilito fino all'autoestinzione o al raggiungimento di un valore specifico della lunghezza del danno. Le portate di ossigeno e azoto in quel momento possono essere utilizzate per calcolare il valore limite dell'indice di ossigeno del campione. La norma cinese GB/T 5454-1997 stabilisce che il valore limite dell'indice di ossigeno di un campione è determinato dalla percentuale di ossigeno necessaria affinché il campione si autoestingua dopo una combustione di esattamente 2 minuti o affinché la lunghezza del danno raggiunga esattamente 40 mm.

3.Test di combustione superficiale

Per i rivestimenti per pavimenti, è possibile utilizzare il metodo della sorgente di radiazione termica o il metodo della tavoletta. Il metodo della sorgente di radiazione termica utilizza una piastra di radiazione termica alimentata a gas combustibile, inclinata di 30°, rivolta verso il campione di pavimento posizionato orizzontalmente.

4. Altri metodi di prova

Per rendere le condizioni sperimentali più vicine alla situazione reale, alcuni paesi hanno istituito piccoli laboratori, come gli Insurance Industry Laboratories (LIL) negli Stati Uniti. Tuttavia, questi piccoli laboratori sono altamente arbitrari e limitati, si basano principalmente sull'esperienza e si discostano notevolmente dalle reali situazioni di incendio. L'Europa ritiene che in determinate situazioni speciali si debbano utilizzare direttamente test standard su larga scala, come il test della parete d'angolo. Il test della parete d'angolo è più vicino alle reali situazioni di incendio.

Prodotti relativi

-

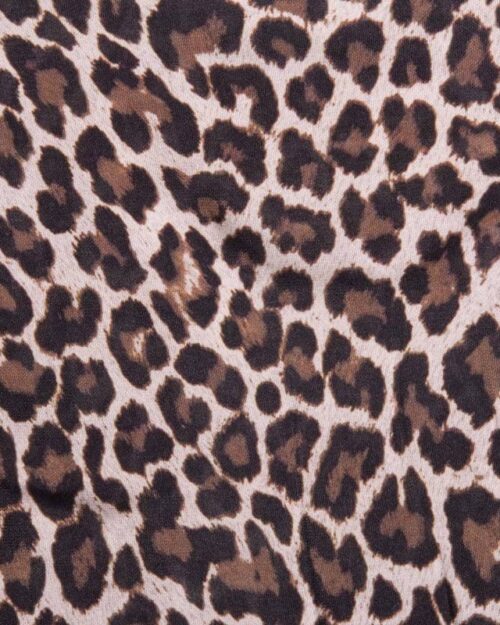

L: 150 cm | Peso: 220 g/m²#0201 Bianco#0402 Marrone#0802 Giallo#1202 ViolaBG-K15

-

L: 150 cm | Peso: 60 g/m²BG-223

-

L: 155 cm | Peso: 235 g/m²#0501 Rosa chiaro#0901 Verde chiaroBG-L34

-

L: 155 cm | Peso: 235 g/m²BG-L33-402

-

L: 155 cm | Peso: 235 g/m²

Produttore all'ingrosso di tessuti in viscosa e rayon ignifughi per abbigliamento

BG-L33-101 -

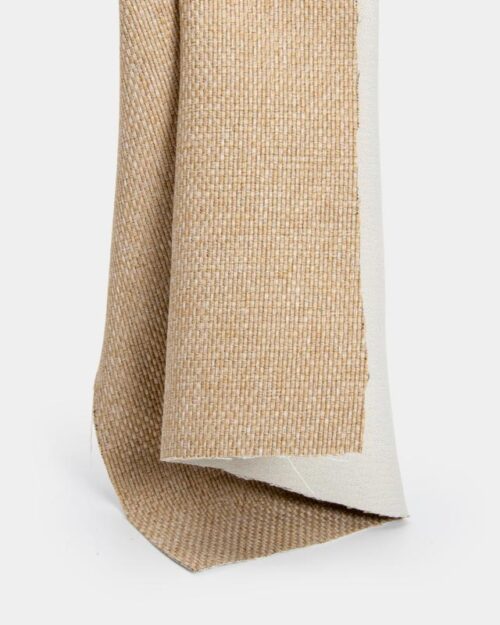

L: 150 cm | Peso: 395 g/m²

Tessuto per tende oscuranti in lino ignifugo certificato NFPA 701 per progettitel

BG-C8 -

L: 300 cm | Peso: 320 g/m²

Tessuto per tende oscuranti al 95%, ignifugo, effetto lino, per progetti alberghieritel

#0402 Marrone#0603 Rosso scuroBG-C10 -

L: 150 cm | Peso: 450 g/m²BG-C7-201

-

L: 150 cm | Peso: 265 g/m²BG-C6-201

-

L: 137 cm | Peso: 370 g/m²

Tessuto per tappezzeria in PVC ignifugo ad alta resistenza per sedute commerciali ad alto traffico

BG-221