The Necessity of Antibacterial and Mold-Proof Fabric.

There are many microorganisms on the surface of human skin, some of which are beneficial bacteria for the human body, while others are pathogenic bacteria.

These microorganisms obtain nutrients from human secretions, sweat, and shedding skin, and undergo metabolic processes of growth, reproduction, and death. At the same time, the fatty acids and lactic acid in sweat and secretions can kill a variety of microorganisms. The mutual killing and inactivation of microorganisms contribute to their balance and coordination in quantity, which generally does not harm the human body.

Once this balance is disrupted, leading to bacterial imbalance, a small number of pathogenic bacteria will multiply rapidly and pose a threat to human health through the skin, respiratory tract, digestive tract, and mucous membranes of the reproductive tract.

Bacteria, fungi, and dust mites can cause significant damage and lead to various health issues. They can produce odors in underwear and sportswear, breed extensively in medical environments, cause allergic reactions, and may cause stains on indoor furnishings and other household items.

Microbial growth can also erode outdoor textiles, such as awnings, tents, or lawn furniture, and cause discoloration and degradation.

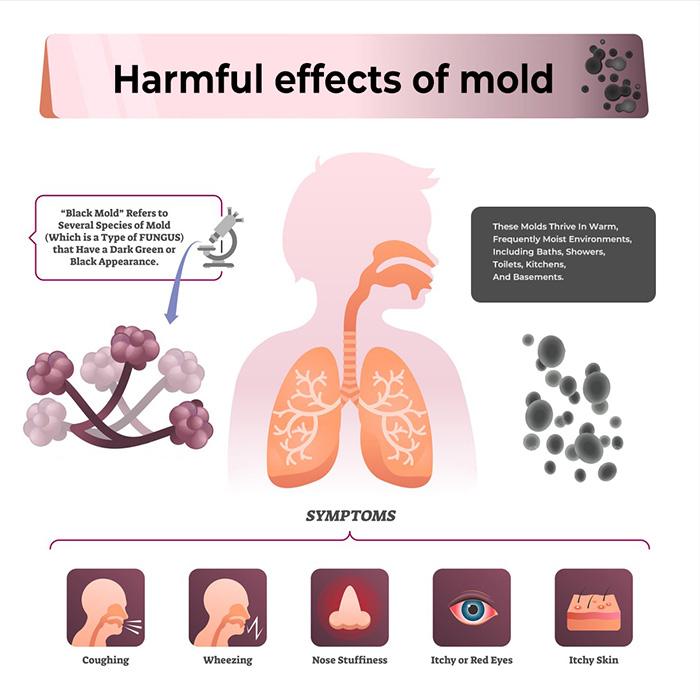

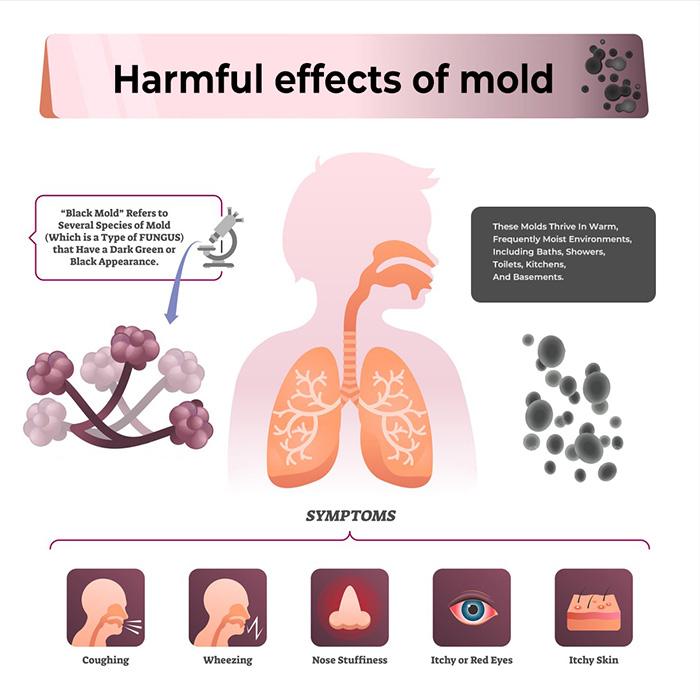

Mold is a type of fungus that can be found in almost any environment, including the air.

There are many different types of mold, and “black mold” usually refers to a type called Stachybotrys chartarum. Other common types include Alternaria, Aureobasidium, and Chaetomium.

It is important to note that mold in its early stages produces a musty odor and can be easily removed from surfaces. However, mold growth indicates that the fungus has matured and become more difficult to remove.

Fungi reproduce through spores and can proliferate on surfaces that are moist and rich in fibers, such as fiberboard, wood, gypsum board, and plasterboard, as well as in areas with small amounts of seepage or water leaks.

Harmful Effects of Mold

When black Aspergillus grows on fabrics, its spore masses appear black, causing the fibers to turn black, while Penicillium is yellow, and green mold is green. The branching spore fungus is brown, and so forth.

During their metabolic processes, molds and bacteria produce ethylene glycol, citric acid, oxalic acid, lactic acid, acetic acid, and other compounds, leading to unpleasant or peculiar odors, elevated fabric temperature, reduced luster, the development of mold spots, and potential harm to human health through skin contact or the respiratory system.

Black mold can produce toxins. It releases so-called mycotoxins, which are highly harmful to building residents. Of course, some individuals are more sensitive to fungal spores than others and may develop respiratory syndrome after inhaling small amounts of spores.

However, a place with a significant amount of mold toxins can lead to fungal poisoning in healthy individuals, depending on the concentration of mycotoxins, the duration of exposure to the toxins, and other contributing factors.

Exposure to fungi is more harmful for infants and young children. Research suggests that children exposed to mold may be more susceptible to developing asthma. In 2009, the World Health Organization released the “WHO Guidelines for Indoor Air Quality: Dampness and Mold,” which offered a thorough review of scientific research on health issues associated with buildings and biological agents linked to dampness. The report concludes that the most significant impact of mold is to increase the prevalence of respiratory syndrome, allergies, and asthma, as well as to interfere with the immune system.

Therefore, to prevent mold growth during the storage, transportation, and pre-sale storage of dyed fabrics, it is essential to add fungicides into the treatment process. Additionally, applying antibacterial and antifungal finishes is crucial to inhibit mold growth.