Wat is inherent vlamvertragend verduisteringsdoek en wat is lichtwerend doek?

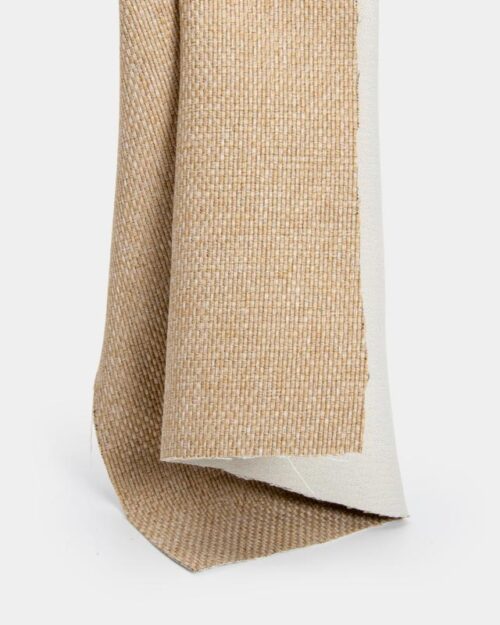

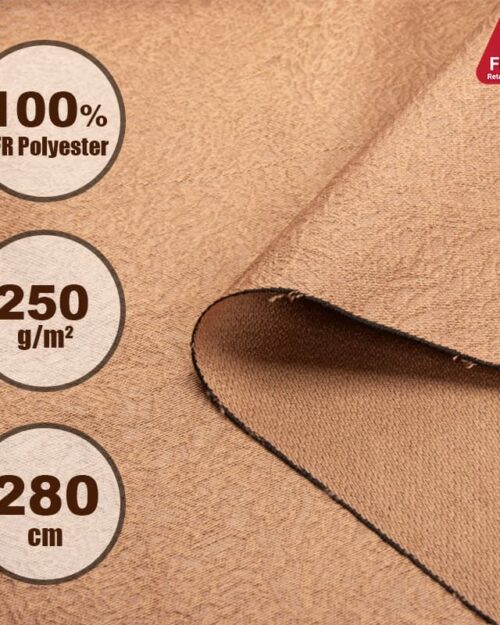

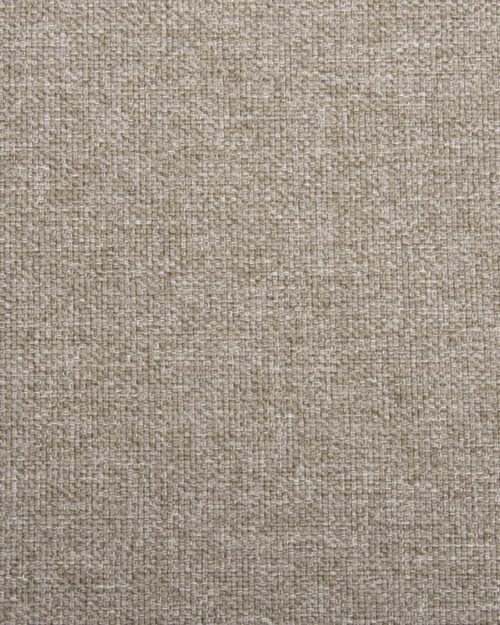

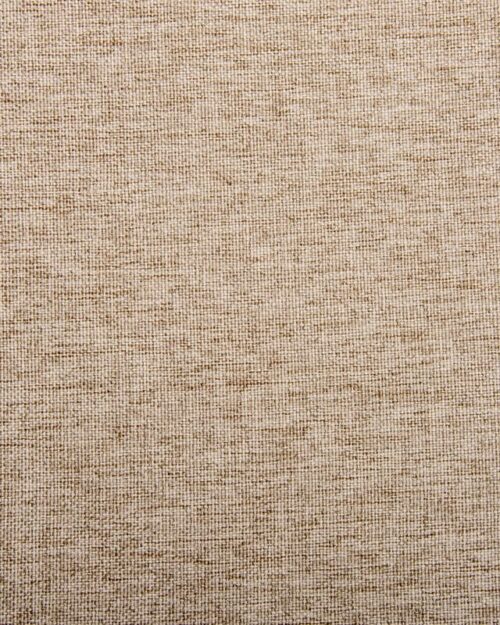

BEGOODTEX Inherent Flame Retardant blackoutstof is een stof die permanente vlamvertragende eigenschappen combineert met een verduisterende werking. De stof is gemaakt van BEGOODTEX' drielaagse, permanent vlamvertragende polyestergaren (Dimout Fabric), met een verduisteringsgraad vantel95%. De coating van de verduisterende stof, bestaande uit BEGOODTEX' vierlaagse schaduwcoating en vlamvertragend polyestergaren, kan een verduisteringsgraad van 100% bereiken. Deze stof biedt uitstekende permanente vlamvertragende en verduisterende eigenschappen en blokkeert effectief de indringing van zonlicht en ultraviolette straling.