Tecido FRStaticGuard

O tecido antiestático é um tipo de tecido projetado para evitar o acúmulo de eletricidade estática. É comumente usado em instalações de produção e salas limpas para evitar danos a equipamentos eletrônicos sensíveis.

O que é um tecido antiestático?

O tecido antiestático, também conhecido como pano antiestático, é um tipo de material que impede o acúmulo de eletricidade estática. Suas propriedades antiestáticas baseiam-se em dois mecanismos: dissipação e neutralização de carga.

Quando um objeto é aterrado, a eletricidade estática no tecido é neutralizada pela descarga corona das fibras condutoras, e qualquer eletricidade estática residual pode ser dissipada para o solo através dessas fibras. Se as fibras condutoras não estiverem aterradas, a descarga corona, mesmo que fraca, ainda consegue dissipar a eletricidade estática.

Perigos da eletricidade estática

Efeitos do desempenho de uso nas roupas

A eletricidade estática gerada por roupas feitas de materiais diferentes pode fazer com que as roupas se enrosquem umas nas outras, tornando-as desconfortáveis de usar. Quando a roupa e a pele têm cargas opostas, elas podem aderir uma à outra, causando dificuldades ao caminhar.

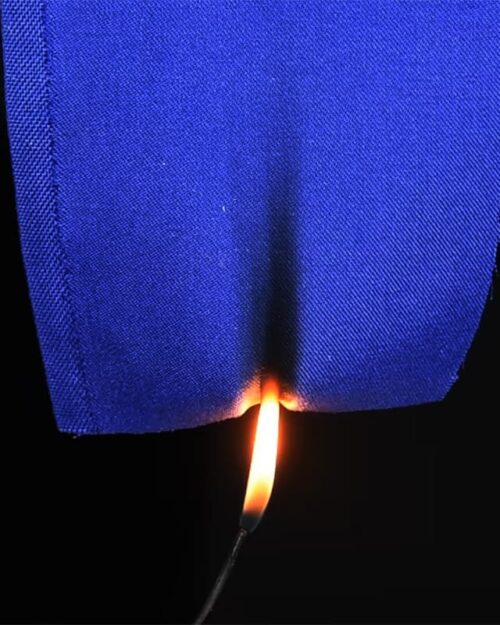

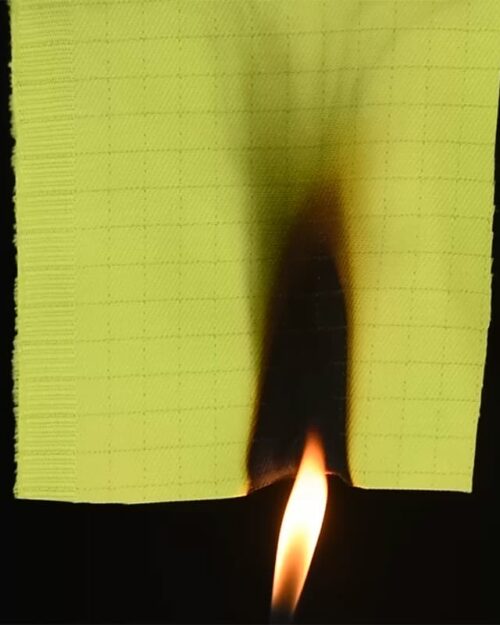

Causas de Acidentes

O uso de roupas sintéticas pode gerar uma grande quantidade de eletricidade estática, que pode se acumular na superfície das roupas. A carga estática acumulada pode produzir faíscas ao romper o espaço de ar. A energia das faíscas é suficiente para inflamar gases inflamáveis e explosivos nas proximidades, causando incêndios ou até mesmo explosões.

Impacto na qualidade dos produtos têxteis

Durante o processo de abertura das fibras soltas, a eletricidade estática faz com que elas grudem na estrutura da máquina, nas tubulações e em outras superfícies. Isso resulta em espessura irregular da camada de fibras produzida e também causa dificuldades na produção devido a emaranhamento, compressão e enrolamento.

Indústrias que utilizam tecidos antiestáticos:

LABORATÓRIOS

QUARTOS LIMPOS

ÁREAS ATEX

AUTOMÓVEIS

Princípios dos materiais têxteis antiestáticos:

Geralmente, existem duas maneiras pelas quais a eletricidade estática é gerada:

1. Eletricidade estática gerada por contato.

2. Eletricidade estática gerada por indução.

A eletricidade estática gerada por contato deve-se principalmente ao movimento de cargas. Quando dois objetos entram em contato e se friccionam, a superfície de um objeto começa a acumular cargas positivas enquanto a superfície do outro fica carregada negativamente, resultando em eletricidade estática.

A eletricidade estática gerada por indução ocorre quando um material condutor está próximo de um condutor ou isolante. As cargas começam a se acumular no lado do condutor ou isolante mais próximo do material condutor. Após um período prolongado de indução, as cargas positivas e negativas do condutor ou isolante se separamtel, levando à geração de eletricidade estática.

Ambos os casos podem ser referidos como efeito de transferência de carga. Antiestático refere-se à capacidade do tecido antiestático de minimizar o efeito de transferência, prevenir o acúmulo de eletricidade estática, reduzir o atrito ou o contato com o produto e atingir o objetivo de evitar o acúmulo de eletricidade estática. A seguir, três métodos comumente utilizados:

Métodos antiestáticos para têxteis

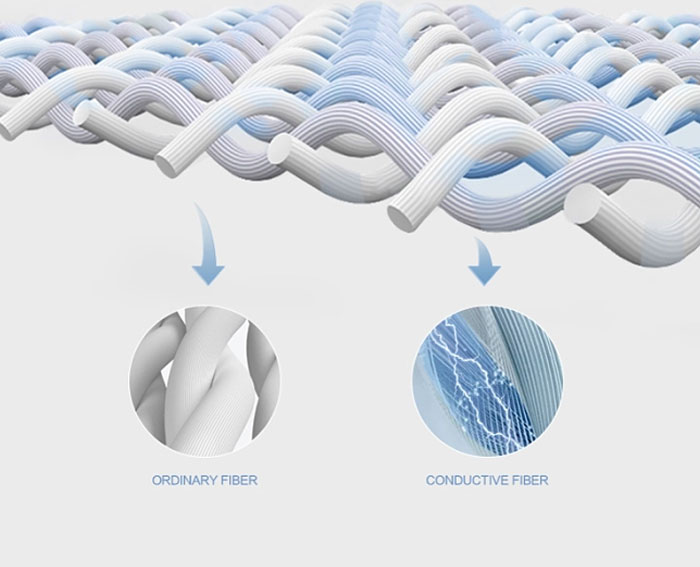

Os métodos para tratamento antiestático de têxteis envolvem principalmente o aumento da condutividade das fibras e a melhoria da umidade do ambiente circundante. O método mais básico e importante é reduzir a resistência elétrica das fibras e aumentar sua condutividade. Existem três métodos principais para tratamento antiestático de têxteis:

Tratamento de tecidos com agentes antiestáticos; Modificação das fibras por meio da enxertia de grupos hidrofílicos, mistura ou entrelaçamento com fibras hidrofílicas; Mistura ou entrelaçamento com fibras condutoras.

Os mecanismos dos dois primeiros métodos consistem em aumentar a absorção de umidade do tecido, diminuir seu isolamento e acelerar a dissipação da eletricidade estática. Portanto, seus efeitos podem não ser duradouros ou significativos em ambientes secos ou após lavagens repetidas.

O terceiro método pode resolver de forma permanente e eficiente o problema da eletricidade estática em tecidos. Ele pode ser utilizado em roupas funcionais especiais, como uniformes de trabalho antiestáticos.

Produção de fibras e tecidos antiestáticos

1. Método antiestático externo

O método de aplicação de agentes antiestáticos externos na superfície das fibras é conhecido como tratamento de superfície, que pode ser categorizado em métodos de tratamento antiestático temporários e duráveis.

(1) Tratamento antiestático temporário. Geralmente, métodos de pulverização externa, impregnação e revestimento são usados para evitar interferência estática durante a fabricação e processamento de fibras.

(2) Tratamento antiestático durável. O tratamento antiestático durável é obtido pela atração de íons de carga elétrica oposta à superfície das fibras por meio de reticulação via tratamento térmico ou pela adesão a um suporte de resina. Isso resulta em um certo nível de durabilidade, resistência à lavagem, resistência ao atrito e outras propriedades.

2. Método antiestático interno

Os três métodos a seguir são usados para incorporar agentes antiestáticos nas fibras:

(1) Modificar o polímero da fibra antes da fiação. Normalmente, compostos hidrofílicos são copolimerizados com monômeros de fibra antes da fiação.

(2) Use um método de fiação de mistura para misturar o polímero com agentes antiestáticos ou use um método de fiação composta.

(3) Revestir a superfície da fibra com um metal condutor ou negro de carbono (que na verdade faz parte do tratamento de superfície), ou utilizar fiação composta para produzir fibras antiestáticas que contenham negro de carbono.

Vantagens do tecido antiestático BEGOODTEX:

Alta condutividade e desempenho eletrostático superior. Fibras metálicas com espessura de até 6,5 µm apresentam excelente condutividade, dissipando cargas estáticas de forma eficaz.

Confortáveis de usar, as fibras e os fios ultrafinos e ultramacios se integram perfeitamente às roupas, mantendo um alto nível de conforto.

Excelentes propriedades de lavagem. Mesmo após múltiplas lavagens industriais, as características e o desempenho antiestático da roupa não se alteram.

Prevenir o mau funcionamento de instrumentos elétricos através da dissipação de ESD é essencial para proteger diversos equipamentos elétricos dos efeitos adversos das cargas estáticas.

Longa vida útil: A excelente durabilidade aumenta a longevidade do tecido.

Aplicações de tecidos com propriedades retardantes de chama inerentes ( RCI ) e antiestáticas

1. Indústria Eletrônica: Tecidos antiestáticos são amplamente utilizados em roupas de trabalho e luvas em oficinas de produção para evitar interferências eletrostáticas durante o processo produtivo. O tecido também protege os componentes eletrônicos contra riscos eletrostáticos, garantindo a qualidade e o desempenho estável dos componentes.

2. Área Médica e de Saúde: Tecidos antiestáticos são utilizados em aventais cirúrgicos, toucas cirúrgicas, protetores de calçados cirúrgicos, etc. Esses produtos podem reduzir eficazmente o problema do acúmulo de carga estática.

3. Indústria petroquímica: Tecidos antiestáticos podem ser utilizados na indústria petroquímica para equipamentos de proteção, como roupas, luvas e protetores de calçados antiestáticos, para mitigar incêndios e explosões provocados por eletricidade estática.

4. Aeroespacial: Tecidos antiestáticos podem ser utilizados na indústria aeroespacial para equipamentos de proteção, como roupas, luvas e protetores de calçados antiestáticos, para evitar interferências e danos causados por eletricidade estática.

5. Indústria de Energia: Tecidos antiestáticos podem ser utilizados na indústria de energia para equipamentos de proteção, como roupas, luvas e protetores de calçados antiestáticos, para prevenir incêndios e explosões causados por eletricidade estática.

6. Indústria Automotiva: Tecidos antiestáticos podem ser utilizados na indústria automotiva para equipamentos de proteção, como roupas e luvas de trabalho, a fim de evitar interferências estáticas e danos aos equipamentos eletrônicos dos automóveis.

Produtos Relativos

-

-

-

#0302 Cinza#0602 Vermelho#0702 Laranja

-

L: 150 cm | Peso: 280 g/m²BG-L19-901

-

L: 150 cm | Peso: 200 g/m²

Tecido antiestático FR de aramida 1414 200g/m², tecido protetor preto

BG-L51-101 -

L: 150 cm | Peso: 160 g/m²

Tecido antiestático FR de aramida 1414 160g/m², tecido industrial preto

BG-L50-101 -

L: 150 cm | Peso: 150 g/m²

Tecido antiestático FR de aramida 1414 150g/m², tecido leve preto

BG-L49-101 -

L: 150 cm | Peso: 200 g/m²

Tecido antiestático FR de aramida 1414 200g/m², preto, para vestuário industrial

BG-L48-101 -

L: 150 cm | Peso: 200 g/m²#1102 Azul#1103 Azul EscuroBG-L43