Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Introduction: Is the nursing home safe? The answer largely depends on the facility’s passive fire protection capabilities. While modern nursing homes are generally equipped with smoke detectors and sprinkler systems, these active measures are often insufficient to counter the smoke and toxic threats faced by residents with limited mobility. The safety of a nursing home involves not only emergency response but also whether interior soft furnishings, such as curtains and bed sheets, possess self-extinguishing properties when exposed to ignition sources. By adopting high-standard flame-retardant materials, fire risks can be minimized at the source, truly ensuring the residential safety of the elderly.

Fire risk management in nursing homes is unique because its core challenge lies in the high vulnerability of personnel combined with significant evacuation delays. Elderly residents generally experience varying degrees of physiological decline, making their escape time in a fire far exceed that of standard residential occupants.

Comparison of Fire Risk: Nursing Homes vs. Standard Housing

| Risk Assessment Dimension | Standard Housing Environment | Nursing Care Environment |

|---|---|---|

| Evacuation Response Time | 3 to 5 minutes (Independent) | 15 to 30 minutes (Assisted) |

| Sensitivity to Smoke Toxicity | Moderate | Extreme (High prevalence of respiratory diseases) |

| Passive Fire Protection Grade | General Residential Grade | Medical/Contract Grade IFR |

| Compliance Audit Frequency | Low | Extremely High with legal liability chains |

Passive fire protection design in nursing homes limits the spread of fire through the non-combustible properties of materials rather than relying solely on external firefighting measures. Begoodtex integrates flame-retardant monomers into the polyester molecular chain through copolymerization, endowing the fabric with permanent non-combustible properties at a physical level. This design effectively prevents vertical fixtures like curtains from becoming fire propagation paths, controlling the scale of the fire before automatic sprinklers activate.

Curtains and blackout fabrics represent the largest vertical flammable surfaces in a room. Using Begoodtex textiles that comply with NFPA 701 or DIN 4102 B1 standards ensures that the material only undergoes local carbonization upon contact with an open flame, without causing extensive fire spread or dangerous molten dripping, thereby preventing fire from jumping between furniture items.

For the elderly, the primary cause of death in fires is smoke asphyxiation rather than flame burns; therefore, the smoke production volume of materials directly determines the success rate of evacuation. Begoodtex IFR polyester does not contain halogen elements during thermal decomposition, resulting in extremely low smoke production and no release of highly corrosive toxic gases. This low-smoke characteristic maintains visibility in escape routes and reduces the risk of acute respiratory tract damage in the elderly.

Risk Assessment of Combustion Products from Different FR Materials

| Indicator Item | Traditional Chemical Coated FR Fabric | Begoodtex IFR Permanent FR Fabric |

|---|---|---|

| Smoke Density Value (Ds) | Relatively High (Due to chemical reagents) | Extremely Low (Stable molecular structure) |

| Halogen Gas Release | May contain Chlorine/Bromine | Halogen-Free |

| Smoke Transparency | Low (Obstruction of escape routes) | High (Conducive to maintaining visibility) |

Bedding and sheets in nursing homes must pass rigorous smoldering and ignition tests as they represent the first line of defense closest to the human body. Begoodtex IFR bedding complies with the British BS 7175 Source 5 (commonly known as Crib 5) standard, meaning the bedding remains non-combustible even under high heat source intensity. This performance provides excellent defense against local fires caused by smoking or improper use of electrical appliances.

The Source 5 wood crib test simulates an ignition source with a significant heat release rate. Begoodtex bedding passes this test, ensuring that if a heat source like a space heater or local flame contacts the bed surface, the fire will be restricted to a minimal area and extinguish rapidly, protecting bedridden residents from harm.

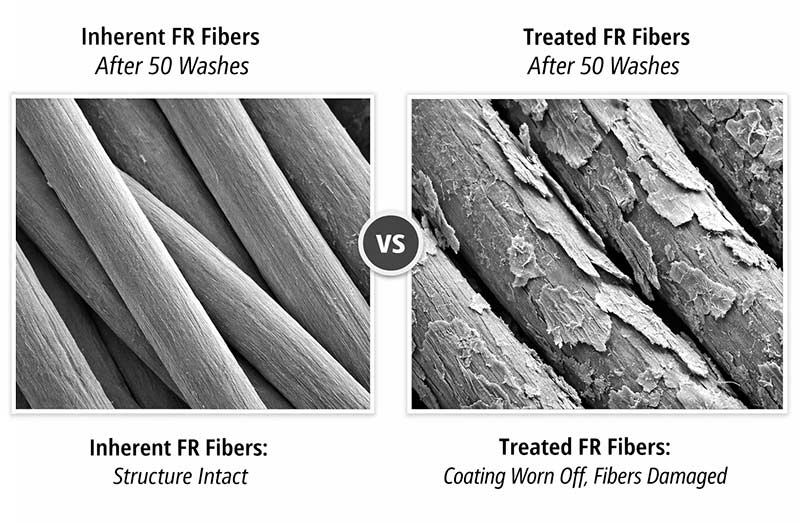

Laundering stability is a core indicator for assessing fire safety compliance in nursing home textiles, as hygiene requirements necessitate frequent high-temperature industrial washing. The flame-retardant properties of Begoodtex IFR fabrics originate from within the fiber; after more than 50 industrial washes at 75 degrees Celsius, the flame-retardancy ratings remain identical to pre-wash levels. This is fundamentally different from fabrics that achieve flame retardancy through surface chemical coatings.

Standard coated FR fabrics lose their fire resistance during washing due to the physical detachment and hydrolysis of chemical reagents. Begoodtex utilizes polymerization technology to firmly bond flame-retardant molecules with polyester long chains, keeping the Limit Oxygen Index stable at over 32 percent even under high-intensity mechanical agitation and chemical detergents.

Although Begoodtex fabrics possess inherent flame-retardant properties, improper maintenance can lead to the deposition of flammable contaminants, creating an “obscuring effect” on the surface. Standard operating procedures must be established in nursing homes to prevent the accumulation of surface oils, dust, or chemical residues. Regular professional cleaning is not just for aesthetics but to ensure the cleanliness of the material surface, allowing its self-extinguishing function to perform correctly.

From a Total Cost of Ownership (TCO) perspective, high-quality inherent flame-retardant fabrics actually save significant hidden costs for nursing homes. Although the initial procurement price is slightly higher than standard or chemically treated fabrics, the long lifespan and maintenance-free nature of Begoodtex products (no need for periodic re-spraying) significantly reduce long-term operational expenses. Furthermore, using compliant fabrics with international certifications can effectively mitigate legal litigation risks and heavy insurance premium pressures resulting from fire accidents.

Traditional coated FR fabrics require re-certification and chemical re-treatment every two years or after major washes, incurring additional costs and potentially leading to fabric stiffening or scrapping. The Begoodtex IFR solution solves compliance issues once and for all, with annualized operating costs far lower than temporary treatment solutions.

Nursing care institutions must provide complete material performance documentation during fire audits to ensure the authentic compliance of utilized textiles. Begoodtex provides customers with a full suite of reports, including physical performance tests and chemical safety evaluations. Beyond combustion tests, parameters such as tensile strength, shrinkage, and color fastness are also key indicators of whether a material is suitable for high-intensity nursing environments.

The safety of a nursing home relies heavily on the integrity of its passive fire protection system. The analysis of Begoodtex inherent flame-retardant textiles demonstrate that selecting fabrics with high flame-retardant stability, low smoke-tox release rates, and excellent laundering durability is an indispensable part of a nursing home fire safety solution. This not only effectively prevents early-stage fires from evolving into catastrophic disasters but also provides the most basic survival guarantee for the elderly. Facility managers should consider the life-cycle costs and legal responsibilities, opting for IFR textile products supported by international certifications to build a truly secure elderly care environment.

Current IFR technology allows modified polyester fibers to achieve a softness, drape, and breathability almost identical to standard textiles, causing no tactile discomfort to residents.

No. The flame-retardant factors are integrated within the molecular chain. UV rays will only cause slow aging of the fiber but will not alter its chemical fire resistance, unlike coated fabrics which are susceptible to photo-decomposition.

Spraying provides only temporary surface protection that washes or wears away over time. Its reliability is far lower than Begoodtex materials, which are flame-retardant from the fiber production stage.

Begoodtex products are rigorously tested under OEKO-TEX 100 and contain no allergenic or carcinogenic chemicals. Their safety reaches the infant-use level, making them ideal for sensitive elderly skin.

No. Professional Begoodtex IFR polyester undergoes anti-dripping modification. Upon contact with fire, it shrinks and carbonizes rapidly, minimizing the risk of secondary fires caused by molten droplets igniting floor materials.V1.2 (English Translation)