Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

The automotive industry operates under stringent safety mandates where interior materials, particularly seat fabrics, must provide a critical barrier against fire propagation. This article serves as a comprehensive technical guide to automotive interior seat flame retardant (FR) fabrics, focusing on the integration of high-performance fire safety with the rigorous demands of public transit, school buses, and commercial coaches. As a specialized R&D expert at Begoodtex, my objective is to delineate the intersection of polymer science, textile engineering, and global safety standards. We will explore how specific fiber compositions, eco-friendly FR chemistries, and advanced manufacturing techniques like jacquard weaving and solution-dyeing converge to create materials that not only meet legal requirements such as FMVSS 302 and ECE R118 but also ensure passenger survival through low smoke emission and non-toxic profiles. This deep dive is designed for procurement professionals, automotive engineers, and safety compliance officers seeking authoritative data on the next generation of automotive upholstery.

The fundamental baseline for automotive seat fabric safety is dictated by regional fire safety standards which primarily measure the horizontal and vertical burn rates of interior materials. While the US standard FMVSS 302 sets a maximum burn rate of 102 mm/min, European regulations for M3 category vehicles (coaches and buses) under ECE R118 are significantly more rigorous, requiring testing for melting behavior (Annex 7) and vertical burn rate (Annex 8). Compliance is not merely a legal hurdle but a critical engineering metric that determines the fabric’s polymer density and flame retardant concentration.

Table 1: Comparative Analysis of Primary Flame Retardant Standards

| Standard | Region | Primary Test Method | Key Metric / Threshold | Application Scope |

|---|---|---|---|---|

| FMVSS 302 | USA/Global | Horizontal Burn Rate | Max 102 mm/min | All Passenger Vehicles |

| ECE R118 Annex 6 | EU / International | Horizontal Burn Rate | Max 100 mm/min | Coaches and Buses (M3) |

| ECE R118 Annex 8 | EU / International | Vertical Burn Rate | Max 150 mm/5s (ignition) | Vertical Curtains/Interior |

| GB 8410 | China | Horizontal Burn Rate | Max 100 mm/min | All Motor Vehicles |

| ISO 3795 | International | Horizontal Burn Rate | Standardized Method | Road Vehicles, Tractors |

In the event of a vehicle fire, smoke inhalation and toxic gas exposure are often more lethal than heat. Low Smoke Non-Toxic (LSNT) technology for automotive seats involves the use of specialized synergists that interfere with the radical chain reaction in the gas phase or promote the condensed phase mechanism. By reducing the smoke density (measured by Ds max) and limiting the emission of lethal gases such as Hydrogen Cyanide (HCN), Carbon Monoxide (CO), and Nitrogen Oxides (NOx), Begoodtex engineered fabrics provide passengers with the “Golden Time” necessary for safe evacuation.

For public transit and city buses, the toxicity index (CIT) is calculated based on the concentration of specific gases compared to their reference lethal levels. Our LSNT fabrics aim for a CIT value of less than 0.75 under the EN 45545-2 standard logic, which is increasingly being adopted as a benchmark for high-occupancy road vehicles.

The selection of base fiber—Polyester, Wool, Aramid, or Blends—fundamentally dictates the fabric’s inherent flame resistance and its reaction to chemical FR treatments. While synthetic fibers like FR-Polyester are dominant due to cost-efficiency and durability, natural fibers like wool offer inherent nitrogen-rich structures that favor self-extinguishing. Understanding the Limiting Oxygen Index (LOI) of each fiber type is essential; automotive grade fabrics generally require an LOI greater than 28% to ensure they do not support combustion in standard atmospheric conditions.

Table 2: Physical and Thermal Properties of Automotive Fiber Types

| Fiber Type | LOI (%) | Melting Point (Celsius) | Tensile Strength | Primary Advantage |

|---|---|---|---|---|

| FR Polyester | 28 – 32 | 250 – 260 | High | Durability and UV resistance |

| Wool / FR Blend | 24 – 26 | 200+ | Moderate | Natural comfort & low toxicity |

| Meta-Aramid | 29 – 31 | 400+ | Very High | Extreme heat stability |

| Modacrylic | 28 – 33 | 160 – 190 | Moderate | Soft hand feel, blendable |

For city buses, a common high-performance blend consists of 85% FR-Polyester and 15% Nylon or Wool. This combination leverages the strength of synthetics with the flame-retardant synergy of nitrogen-containing fibers, ensuring the fabric survives the 100,000+ Martindale rub test cycles required for heavy-duty transit use.

Public transit seating faces extreme mechanical stress from high passenger turnover, requiring a synergy between abrasion resistance and flame retardant stability. Traditional FR coatings can crack or delaminate under repeated compression and friction, leading to “localized FR failure.” Begoodtex utilizes a molecular-level integration of FR agents into the polymer matrix, ensuring that even after 150,000 Martindale cycles, the fabric maintains its structural integrity and passes the ECE R118 horizontal burn test without compromise.

“The durability of a flame retardant fabric in a city bus environment is measured not on day one, but after five years of service. Mechanical wear must not degrade the chemical fire barrier.”

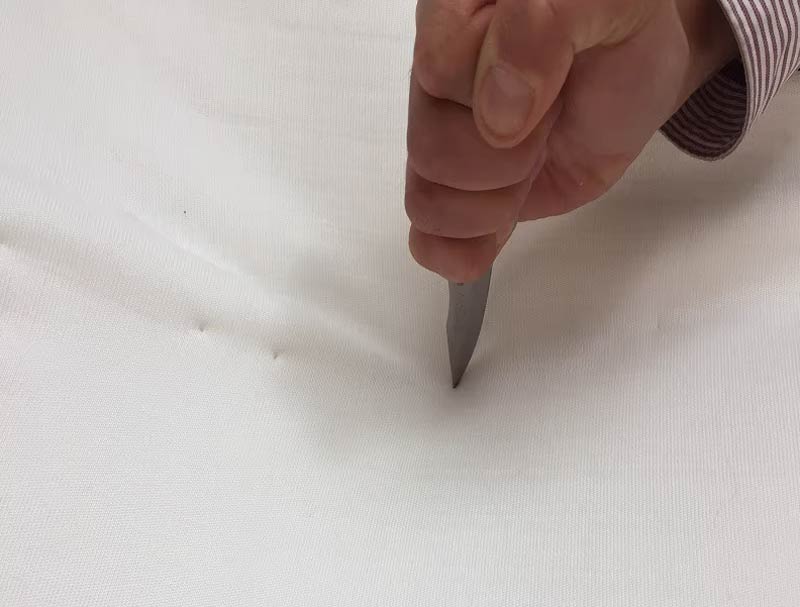

School bus environments necessitate specific protections against intentional damage (vandalism) and high-intensity ignition sources. The fabric must be engineered with high tear strength to resist slashing and an “instant-off” flame response to prevent small fires (e.g., from lighters or matches) from spreading across the cabin. Begoodtex specializes in high-density weaves that prevent the ingress of sharp objects while maintaining the ECE R118 Annex 8 vertical fire safety rating.

The production of Jacquard FR fabrics involves complex yarn management where the aesthetic pattern must not create “weak points” in the fire barrier. In automotive interiors, Jacquard weaves allow for brand-specific designs and textures, but the varying float lengths of yarns can influence the burn rate. At Begoodtex, we calibrate the weave density and yarn twist to ensure that the air permeability of the Jacquard structure does not accelerate the oxygen supply to a potential flame.

Modern automotive interiors are moving away from Decabromodiphenyl Ether (DecaBDE) and other halogenated flame retardants due to environmental and health concerns (REACH/RoHS). Begoodtex employs Organophosphorus and Nitrogen-based FR systems that are non-toxic and environmentally sustainable. These chemicals are permanently bonded to the fiber, preventing “blooming” (surface migration) which can cause skin irritation or fogging on the interior of vehicle windows.

Table 3: Chemical Safety and Regulatory Compliance Standards

| Regulation | Requirement | Begoodtex Solution |

|---|---|---|

| REACH SVHC | No hazardous substances > 0.1% | 100% Halogen-free formulations |

| OEKO-TEX 100 | Skin-friendly pH and no toxins | Class I (Safe for infants) certified |

| VDA 278 | Low VOC and FOG emissions | Water-based, high-fixation FR agents |

| RoHS 3 | Restriction of PBB/PBDE | Compliant phosphorus-based chemistry |

The maintenance of automotive seats is a primary operational cost for fleet owners, necessitating fabrics that are both flame retardant and “Easy-Clean.” Traditionally, adding fluorocarbon-based water repellents (DWR) could interfere with the FR coating’s effectiveness. Begoodtex has pioneered a cross-linking finishing process that allows the integration of C6 or fluorine-free hydrophobic agents with FR properties, enabling the removal of spills, coffee stains, and mud without compromising the safety rating.

Automotive seat fabrics are subjected to extreme UV radiation and temperatures exceeding 80 degrees Celsius behind vehicle glass. This environment can degrade both the fiber strength and the chemical FR agents. Begoodtex utilizes UV-stabilized FR-Polyester yarns and high-energy disperse dyes to ensure that the fabric maintains a Light Fastness rating of Grade 6+ (ISO 105-B02), preventing the fabric from becoming brittle—a state which would significantly increase its flammability.

The choice between solution-dyed (dope-dyed) FR fibers and piece-dyed after-treatments involves a trade-off between cost, lead time, and performance longevity. In solution-dyeing, the flame retardant agent and the pigment are added to the liquid polymer before extrusion into fiber. This results in “Built-in” FR properties that are truly permanent and cannot be washed or worn away, unlike topical treatments that may lose efficacy over time or through cleaning.

For fleet operators, the ability to deep-clean or industrially wash seat covers is vital for hygiene. Begoodtex automotive fabrics are engineered to withstand up to 50 industrial wash cycles at 60 degrees Celsius while maintaining compliance with ECE R118. We conduct “Leaching Tests” to ensure that the FR chemicals do not migrate into the wastewater, which also confirms the longevity of the fire protection for the lifespan of the vehicle.

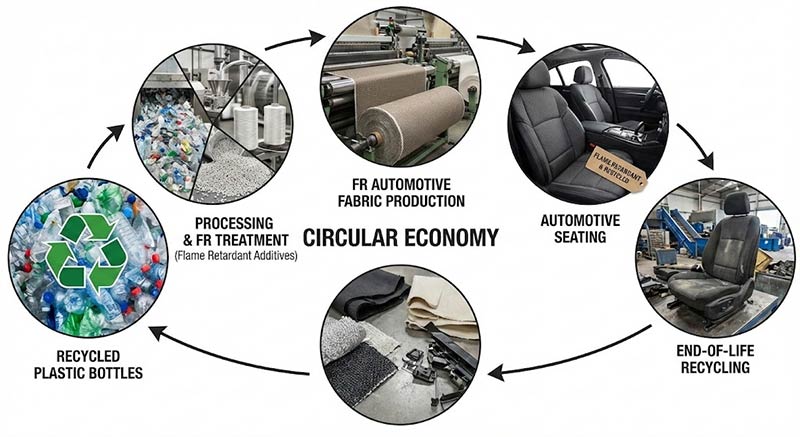

The future of automotive interiors lies in the “Mono-material” concept, where the entire seat—from the fabric to the foam—is made from 100% recyclable polyester. Begoodtex is currently developing FR fabrics made from rPET (recycled Polyethylene Terephthalate) that meet FMVSS 302 standards. This shift supports the Global Automotive Sustainability Roadmap, reducing the carbon footprint of vehicle production without sacrificing the life-safety performance of the interior materials.

A: No, when using Begoodtex solution-dyed FR technology. The FR agents are part of the fiber’s molecular structure. For topically treated fabrics, degradation occurs after 10-15 washes; however, our automotive range is designed for 50+ industrial washes without loss of rating.

A: We comply with VDA 278 standards by using high-boiling point FR agents and eliminating volatile organic compounds (VOCs). This ensures that no chemical vapors condense on the windshield during high-temperature exposure.

A: It is challenging. ECE R118 (especially Annex 8 vertical burn) usually requires a minimum density of 300 g/m2 to provide enough thermal mass to resist ignition. We optimize weave density to achieve the lowest weight possible while maintaining the safety margin.

A: Yes. We engineer specific seam-strength and burst-strength parameters. The FR treatment does not affect the yarn’s elongation at break, ensuring the fabric tears predictably during airbag inflation.

A: Polyester offers vastly superior abrasion resistance (100k+ vs 30k cycles) and UV stability. Cotton-based FR treatments are also prone to leaching and provide poor moisture management in high-traffic public transit.