Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Fire safety is critically important in both residential and commercial environments where fabrics and soft furnishings are widely used. As a result, fire retardant sprays have become a popular and seemingly convenient solution. With just a few applications, ordinary textiles are claimed to gain fire-resistant properties, offering peace of mind without the need to replace existing materials. But does fire retardant spray really work? More importantly, can it provide long-term fire protection?

This article examines the effectiveness, chemical composition, and real-world durability of fire retardant sprays applied to various textile substrates, aiming to help general consumers understand whether these spray treatments can truly be relied upon for long-term fire safety.

Fire retardant spray is a liquid chemical solution, typically water-based, designed to be applied to the surface of existing combustible materials like curtains, upholstery, and carpets. These sprays contain flame-inhibiting chemicals such as ammonium polyphosphate or borate salts that penetrate the outer layer of the fabric. Once the liquid evaporates, the chemical residue remains on the fibers, ready to react if exposed to a heat source. It is categorized as a “topical treatment” or “aftermarket application,” meaning it is added after the textile has already been manufactured and finished, rather than being part of the fiber itself.

Table 1: Technical Composition of Typical FR Sprays

| Component Type | Specific Example | Function in Fire Suppression |

|---|---|---|

| Active Agent | Ammonium Polyphosphate (APP) | Dehydrates fiber to form a protective char barrier. |

| Gas Suppressant | Nitrogen Compounds | Releases non-combustible gases to dilute oxygen. |

| Binding Agent | Polymer Resin (Optional) | Helps the chemical adhere to the fiber surface. |

The protective mechanism of a fire retardant spray relies on a surface-level chemical reaction that occurs at the moment of ignition. When the sprayed fabric is exposed to a flame, the chemicals absorb the heat (an endothermic reaction) and begin to decompose, releasing water vapor or non-flammable gases like carbon dioxide. Simultaneously, the chemical salts promote the formation of a carbonaceous char layer on the fiber’s exterior. This char layer acts as an insulator, blocking oxygen from reaching the core of the fiber and preventing the material from feeding the fire. However, this protection is only as effective as the uniformity of the spray application.

In a controlled laboratory setting, textiles treated with high-quality fire retardant sprays can successfully pass stringent initial flammability tests such as NFPA 701 (for curtains) or BS 5852 (for upholstery). These tests verify that the material does not continue to burn after the ignition source is removed and that the char length remains within acceptable limits. This “Day Zero” performance proves the spray is effective in its original state. However, compliance is often lost quickly once the fabric is put into use, as these tests usually do not account for the natural wear, dust accumulation, or light exposure that occurs in real-world scenarios.

Table 2: Common Testing Standards for Treated Fabrics

| Standard | Applicable Region | Primary Evaluation Metric |

|---|---|---|

| NFPA 701 | USA / Canada | Flame propagation and flaming debris. |

| BS 5867 Part 2 | United Kingdom | Flammability of drapery and window drapes. |

| DIN 4102 B1 | Germany / Europe | Small burner test for building materials. |

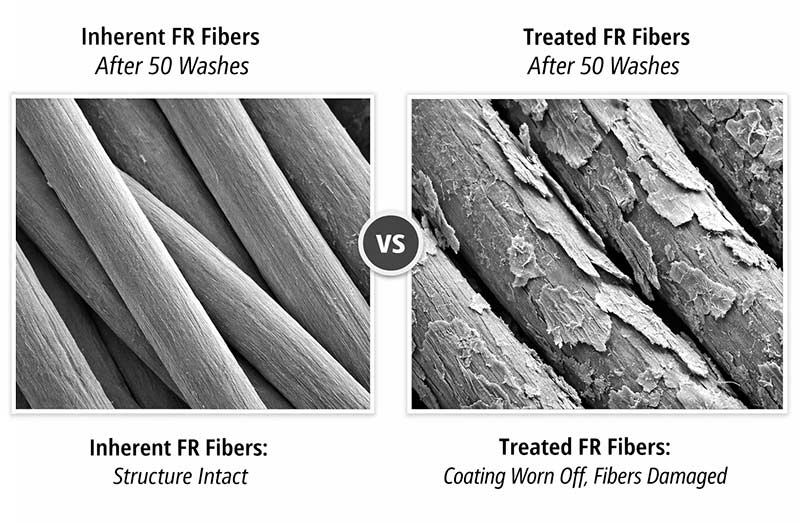

The most significant technical limitation of fire retardant sprays is their lack of durability against moisture and laundering. Because the chemicals are simply coated onto the fiber rather than integrated into its molecular structure, they remain highly susceptible to leaching. A single cycle in a commercial washing machine or even high-pressure steam cleaning will effectively remove the majority of the flame-retardant salts. This transforms a “fire-rated” curtain back into a flammable hazard instantly. Begoodtex addresses this by using Inherent Flame Retardant (IFR) technology, where the protection is part of the fiber polymer, ensuring performance for 50+ washes.

The effectiveness of a topical fire retardant is heavily dependent on the porosity and moisture regain of the target fiber. Natural fibers like cotton, linen, and wool are highly absorbent, allowing the liquid spray to penetrate the yarn core, which provides relatively stable (though still non-permanent) protection. Synthetic fibers such as standard polyester or nylon are non-porous and hydrophobic. In these cases, the spray often fails to bond, resulting in a brittle film on the surface that cracks and falls off over time. This makes sprays an unreliable choice for modern synthetic drapery compared to inherent polyester solutions.

Human safety is a critical concern when using topical fire retardant sprays, as they often contain chemicals that are not fully sequestered within the fabric. When used on upholstery or bedding, these chemicals can transfer to human skin or be inhaled as fine dust as the coating degrades. Some older or lower-end sprays may contain halogens or formaldehyde-releasing agents, which are linked to respiratory issues and skin irritation. Begoodtex focuses on inherent fibers that are Oeko-Tex Standard 100 certified, meaning they are free from harmful substances and are safe for direct skin contact, even for infants.

Applying a chemical spray to a finished textile invariably alters its physical hand-feel and appearance. The salts left behind can make the fabric feel stiff, boardy, or “crunchy” to the touch. In many cases, the chemical residue attracts dust and airborne pollutants more rapidly than untreated fabric, leading to a dingy appearance and a need for more frequent cleaning—which ironically further removes the fire protection. Furthermore, acidic components in some sprays can catalyze the degradation of natural fibers, shortening the overall lifespan of the curtains or furniture significantly.

“The trade-off for temporary fire safety is often the premature destruction of the textile’s aesthetic and structural integrity.”

Relying on fire retardant sprays for legal compliance in public spaces like schools, hospitals, or hotels is technically and administratively challenging. While the fabric may have a certificate at the time of installation, that certificate is often voided the moment the fabric is cleaned or after a specific period (usually 12 months). To remain legally compliant, facility managers must maintain strict re-application schedules and keep detailed logs for fire marshals. Failure to do so can lead to massive liability if a fire occurs. Begoodtex IFR fabrics offer “lifetime compliance,” meaning the fire rating never expires, regardless of the cleaning history.

Table 3: Liability and Compliance Comparison

| Compliance Factor | Spray-Treated Fabric | Begoodtex IFR Fabric |

|---|---|---|

| Certificate Validity | Temporary (Must be renewed) | Permanent (Life of fabric) |

| Post-Cleaning Status | Requires Re-treatment | Retains Compliance |

| Audit Risk | High (Easy to fail field tests) | Zero (Performance is inherent) |

From a financial perspective, fire retardant sprays appear cheaper only as an initial purchase. When calculating the Total Cost of Ownership (TCO) over a five-year period, the spray-treated option is significantly more expensive. The hidden costs include the labor for on-site application, the cost of the chemical itself, the necessity for specialized dry-cleaning (to preserve the coating), and eventually, the premature replacement of the fabric due to chemical degradation. IFR fabrics from Begoodtex require zero maintenance beyond standard cleaning, making them the most economical choice for long-term facility management.

Inherent flame retardant (IFR) technology, such as that utilized by Begoodtex, represents a fundamental shift from “coating” to “engineering.” By modifying the polyester molecule during the polymerization stage, the flame-retardant properties become an inseparable part of the fiber core. This ensures that the protection cannot be washed out, rubbed off, or degraded by the sun. As an R&D expert, I maintain that for any high-traffic or high-risk environment, the reliability of IFR textiles far exceeds the unpredictable performance of topical sprays, providing a truly passive fire safety system that works every time.

Fire retardant sprays provide a functional but temporary solution for localized fire safety. They are effective for one-time events or as an emergency measure for non-FR fabrics, but they fail the tests of durability, long-term compliance, and cost-efficiency. For professional procurement in sectors like hospitality, healthcare, and education, Begoodtex Inherent Flame Retardant textiles are the only technically sound investment, offering permanent, eco-friendly, and skin-safe protection that topical treatments simply cannot match.

Yes, you can apply a certified fire retardant spray to help them meet initial standards like NFPA 701. However, be aware that you will need to re-apply the spray every time the curtains are cleaned or once a year to maintain that certificate.

The most accurate way is a “field flame test” on a small, inconspicuous scrap of the fabric. If the fabric continues to burn after the flame is removed, the spray has leached out or degraded. IFR fabrics avoid this uncertainty entirely.

Many sprays can cause yellowing over time, especially when exposed to UV light or heat. Some also have a mild chemical odor or attract dust which can lead to mustiness. Begoodtex IFR fibers are odorless and UV-stable.

Technically, no. While some industrial coatings are more durable than consumer sprays, no topical treatment is as permanent as an inherent fiber. Coatings eventually fail due to the mechanical and chemical stresses of cleaning.

Yes. Unlike sprayed fabrics that require special care, Begoodtex IFR textiles can be washed with standard detergents. Just avoid silicone-based softeners which could potentially coat the fiber and create a flammable surface layer.V1.1