Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

In the global textile trade, JIS L 1096 is the primary Japanese industrial standard system for evaluating the general physical properties of both woven and knitted fabrics. It serves as the essential quality gateway for entering the Japanese market and partnering with major retailers such as UNIQLO, MUJI, and Nitori. This comprehensive standard covers dozens of testing methods ranging from mechanical strength to comfort and durability, with the latest versions (2010/2020) now consolidating previous standards for knits.

JIS L 1096 is a comprehensive methodology standard developed by the Japanese Industrial Standards Committee (JISC) to evaluate the physical characteristics of textiles, including strength, thickness, air permeability, and shrinkage. The current version, JIS L 1096:2020, integrated and replaced the previous JIS L 1018 standard for knitted fabrics to provide a unified framework for all apparel textiles. A distinguishing feature of this standard is its use of “Letter Methods” (Method A, B, C, etc.) to define specific testing principles based on the fabric’s end-use.

The JIS L 1096 standard is categorized by specific physical properties, each utilizing different “Letter Methods.” Understanding these is critical as results can vary significantly between methods.

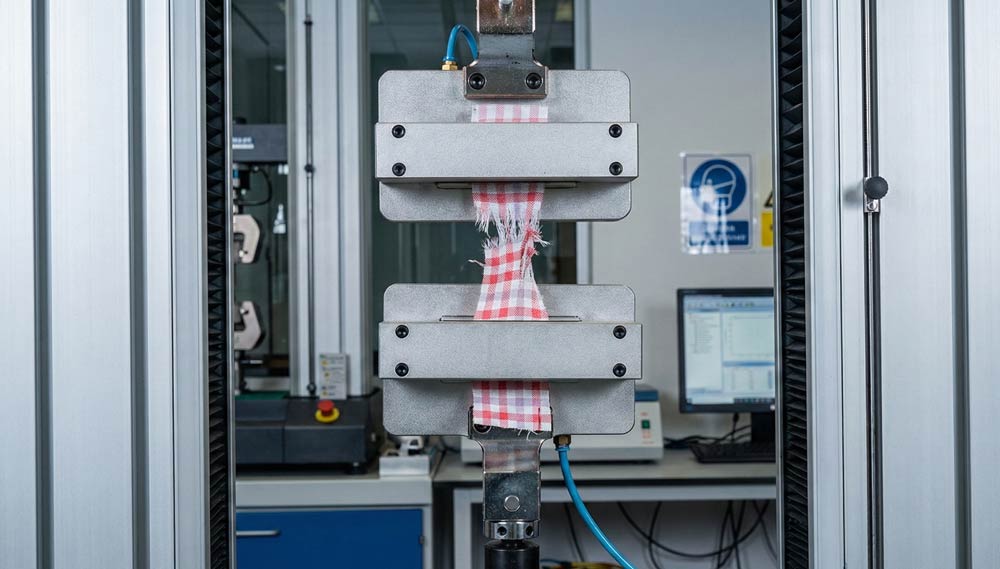

Tensile strength testing measures the force required to break a fabric, with Method A (Strip Method) being the preferred choice for the Japanese market.

Tearing strength evaluates a fabric’s resistance to tearing after an initial cut, where Method D (Pendulum/Elmendorf Method) is the dominant requirement for Japanese apparel.

Seam slippage testing assesses the tendency of yarns to pull apart at a seam under stress, commonly evaluated using Method B (Constant Load Method) in Japan.

Air permeability in Japan is typically tested using JIS L 1096 Method A (Frasier Type), which measures the volume of air passing through a specific area of fabric under a set pressure. This is a vital comfort metric for summer apparel and down-proof linings.

| Test Item | Typical Method | Key Metric |

|---|---|---|

| Air Permeability | Method A (Frasier) | cm³/cm²·s |

| Abrasion Resistance | Method E (Martindale) | Number of friction cycles until breakdown |

| Bursting Strength | Method A (Mullen) | kPa (Primarily for knits) |

Unlike the fragmented ASTM or ISO systems, JIS L 1096 serves as a single “encyclopedia” containing nearly all physical tests in one document.

| Dimension | JIS L 1096 (Japan) | ASTM D Series (USA) | ISO Series (Global) |

|---|---|---|---|

| Tear Preference | Method D (Pendulum) | ASTM D2261 (Tongue) | ISO 13937-1 (Trouser) |

| Tensile Preference | Method A (Strip) | ASTM D5034 (Grab) | ISO 13934-1 (Strip) |

| Slippage Logic | Fixed load, measure distance | Fixed distance, measure load | Fixed load, measure distance |

To pass rigorous Japanese testing, specifically for Slippage and Tearing (Method D), BEGOODTEX recommends the following engineering strategies:

A: The JIS L 1096:2010 update merged and replaced the old JIS L 1018 standard for knits. It is now the unified standard for all woven and knitted apparel textiles.

A: No. JIS L 1096 focuses on physical properties. Flammability testing is covered under JIS L 1091.

A: Method G typically involves hang-drying, whereas Method H uses flat-drying. Knitted fabrics, which deform easily, are generally tested using Method H (flat-dry).

A: No. Formaldehyde testing falls under JIS L 1041. Japan has extremely strict limits for infants (under 24 months), requiring less than 16 ppm.