Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Preface

Have you ever stood in front of your closet, wondering why some T-shirts are breathable and dry while others feel stuffy and uncomfortable? Why do some skirts drape smoothly while others wrinkle easily?

The answer lies in a small word on the clothing label—fiber.

Understanding fibers not only allows you to make wise choices when shopping but also helps you truly comprehend the performance and value of garments. Today, we’ll use a diagram and three major categories to clearly explain “natural, regenerated, and synthetic” fibers, making you a shopping expert from now on!

Simply put, fiber is the DNA of textiles. It determines a garment’s:

From daily wear to functional outdoor gear, choosing the right fiber is choosing half the experience.

In the modern textile industry, fibers are divided into three major categories:

These three form a complete spectrum from “gifts of nature” to “technological innovation.” The following chart clearly illustrates their hierarchical relationship:

For example, Viscose is located in the “regenerated cellulose fiber” category under “man-made fibers”—

it originates from natural plant cellulose but is formed through chemical dissolution and regeneration, belonging to the “semi-natural, semi-synthetic” transitional type of fiber.

Natural Fibers: Gifts from Nature

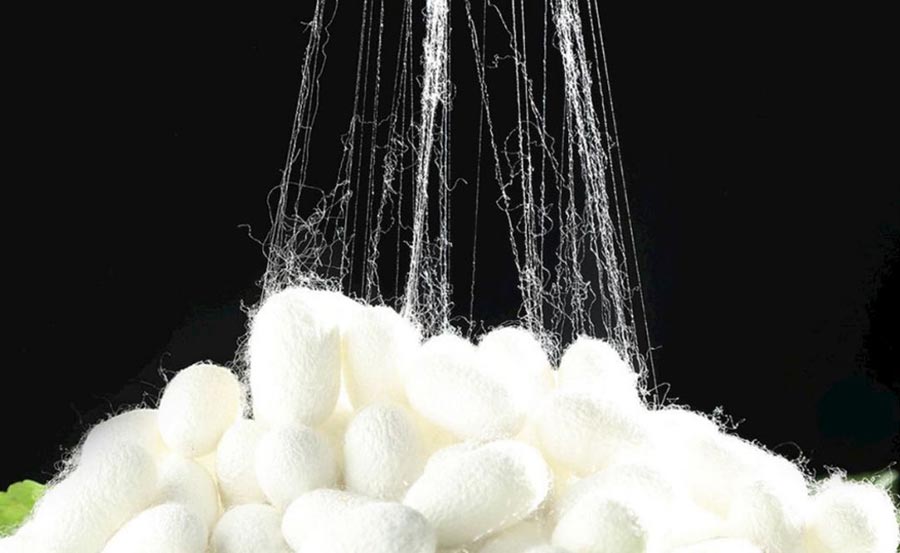

Natural fibers come directly from plants or animals in nature, require no chemical restructuring, and are the earliest textile materials used by humans.

The advantages of natural fibers lie in “comfort and eco-friendliness,” but their disadvantages are high cost, being prone to wrinkling and shrinking, and lower strength.

Regenerated fibers (Regenerated Cellulose Fibers) use natural cellulose from plants as raw material. They extract cellulose from natural substances (like wood pulp, bamboo pulp) and reshape it after dissolution through a chemical process of “dissolving → regenerating → spinning.” It possesses the comfort gene of natural fibers while improving some of their properties.

Typical Representatives and Technical Features

| Name | English Name | Raw Material Source | Process Features | Performance |

| Viscose Rayon | Viscose Fiber | Wood pulp, cotton linter | Classic vulcanization regeneration method (CS₂ + NaOH) | Soft, drapes well, good dyeability, low wet strength |

| Modal | Modal | Beechwood pulp | Improved viscose, HWM structure | High wet strength, smooth feel, low shrinkage |

| Lyocell (Tencel) | Tencel | Wood pulp | Green NMMO solvent method, no sulfur pollution | Eco-friendly, high strength, breathable |

| Cupro | Cupro Fiber | Cotton linter | Cuprammonium solution dissolution method | Smooth, close-fitting, excellent breathability |

| Acetate | Acetate Fiber | Cellulose esterification | Thermoplastic regenerated fiber | Good luster, suitable for linings and fashion |

Expert Tip: Many people mistakenly believe Viscose is purely natural. Although its raw material is natural wood pulp, it belongs to “regenerated fibers” within “man-made fibers” because it undergoes a chemical regeneration process, rather than being a “natural fiber.”

Brief Process Description (using Viscose as an example)

Synthetic fibers are produced through the polymerization of petrochemical raw materials (such as ethylene, benzene, propylene).

Their advantages are high strength, wear resistance, ease of maintenance, and controllable performance, making them the core materials of modern functional textiles.

| Name | English Name | Main Characteristics | Application |

| Polyester | Polyester | High strength, wrinkle-resistant, not easily deformed | Workwear, curtains, sofa fabric |

| Nylon | Nylon | Wear-resistant, good elasticity, low moisture absorption | Sportswear, backpacks, ropes |

| Acrylic | Acrylic | Warm, lightweight, brightly colored | Sweaters, knitwear |

| Spandex | Spandex | Extremely elastic, good recovery | Tights, sportswear |

| Polypropylene | Polypropylene | Lightweight, moisture-proof, cost-effective | Industrial fabrics, carpet backing |

Key Tips: Synthetic fibers can be endowed with properties such as flame retardancy, anti-static, waterproofing, and anti-radiation through a Functional Masterbatch.

| Item | Natural Fibers | Regenerated Fibers | Synthetic Fibers |

| Raw Material Source | Plants and animals | Natural cellulose (wood pulp, etc.) | Petrochemicals |

| Core Advantages | Skin-friendly, breathable, comfortable | Soft, drapes well, good moisture absorption | Wear-resistant, anti-wrinkle, high strength |

| Core Disadvantages | Prone to wrinkling, slightly poor stability | Weaker in wet strength (some types) | Poor breathability, static electricity |

| Eco-friendliness | Excellent (biodegradable) | Medium to excellent (depends on the process) | Poor (difficult to degrade) |

| Representatives | Cotton, linen, silk, wool | Tencel™, Modal, viscose | Polyester, nylon, spandex |

Under the “dual carbon goals” and ESG guidelines, the textile industry is gradually transitioning towards circular regeneration and low-carbon production.

New trends include:

The history of fiber evolution is a process of humanity re-understanding “nature” and “technology.”

From the natural gifts of cotton and silk, to the chemical regeneration of viscose and Tencel, to the technological innovation of functionalized polyester,

each advancement is making textile materials safer, more comfortable, and more sustainable.

A: No. Although it comes from natural wood pulp, it is made through a chemical regeneration process and belongs to “regenerated fibers,” not pure natural fibers.

A: The raw material for regenerated fibers comes from natural cellulose (wood pulp, bamboo pulp, etc.), while synthetic fibers are entirely produced from the polymerization of petrochemical raw materials.

A: Natural fibers (like cotton, linen, silk) are biodegradable; some regenerated fibers (like Lyocell Tencel) have also achieved closed-loop recycling of green solvents, making their environmental performance superior to traditional synthetic fibers.

A: Because they have high strength, good wear resistance, and can be endowed with special properties like flame retardancy, anti-static, and waterproofing through functional masterbatches, making them suitable for industrial and safety protection applications.

A: Natural fibers feel more “raw” and are breathable and comfortable, but they wrinkle and shrink easily; regenerated fibers have a more uniform texture, better drape, and a smoother, softer feel.

A: Parallel development towards “green manufacturing + functional innovation”—based on renewable raw materials, combined with high-performance features like flame retardancy, antibacterial, and anti-static properties, to achieve both comfort and sustainability