Fireproof & Flame Retardant Fabrics: A Complete Protection Guide

Whether you are manufacturing protective clothing for firefighters, designing safety curtains for a theater, or insulating high-temperature industrial pipes, the right material is the difference between safety and disaster.

We bridge the gap between comfort and extreme protection. Our inventory spans critical technologies, primarily focusing on

Inherently Flame Retardant (IFR) fibers (like Aramid, Modacrylic, and Oxidized PAN) where the protection is permanent and integrated into the molecular structure.

Understanding the Technologies

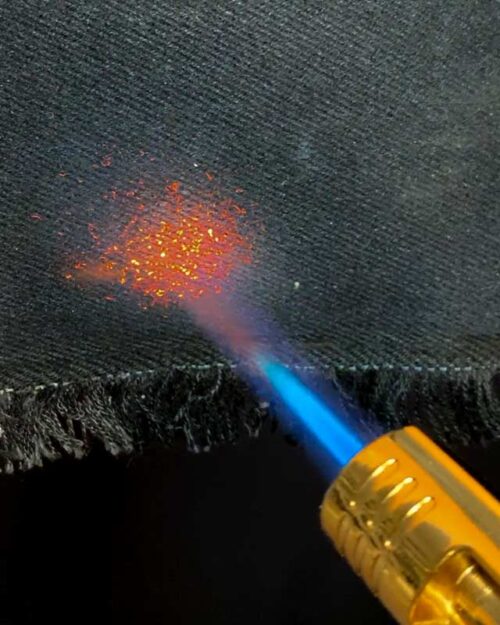

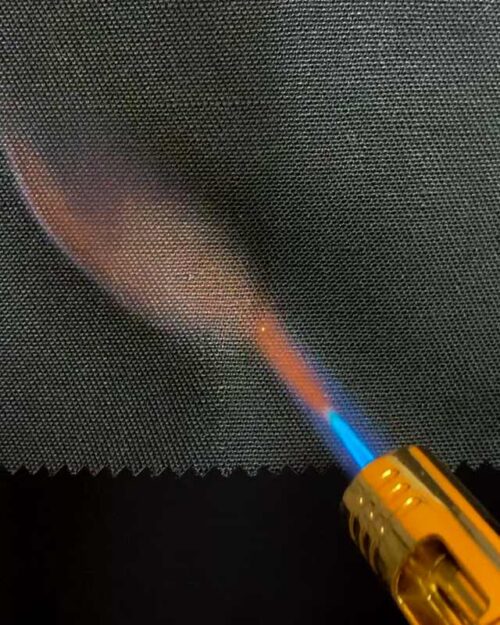

- Inherent FR (IFR): The flame resistance is part of the fiber's chemical structure. It cannot wash out or wear away. Ideal for PPE where long-term durability is non-negotiable (e.g., Aramid, Modacrylic, Viscose).

- Treated FR: Natural fibers are chemically treated to become flame resistant. Modern technology allows these treatments to withstand 50-100 industrial washes.

- Inorganic/High-Heat: Materials like Fiberglass and Oxidized PAN are chemically non-combustible and designed for static heat barriers rather than clothing.

International Standards Overview

Our fabrics are tested against a rigorous matrix of global standards to ensure they perform when it matters most:

- For Personal Protection (PPE): EN ISO 11612 (Heat & Flame), NFPA 2112 (Flash Fire), EN ISO 11611 (Welding), ASTM F1506 (Arc Flash).

- For Architecture & Public Spaces: NFPA 701 (Curtains), DIN 4102-B1 (Construction), EN 13501-1 (Building Elements).

- For Transportation: FAR 25.853 (Aviation), EN 45545-2 (Railway), IMO FTP Code (Marine).

How to Choose the Right Fabric?

| Application Goal |

Recommended Fiber Families |

Key Priority |

| Body Protection (PPE) |

Aramid, Modacrylic, FR Cotton, FR Viscose |

Comfort, Breathability, Non-Melting, Flash Fire Safety. |

| Extreme Heat & Welding |

Oxidized PAN, Fiberglass, Silica |

Temp Resistance (>500°C), Spark Resistance, Thermal Insulation. |

| Interiors & Drapery |

FR Polyester, FR Linen, FR Wool |

Aesthetics, Drape, Washability, Smoke Toxicity Regulations. |

| High Visibility Safety |

Modacrylic Blends |

Fluorescence capable while maintaining FR properties. |

Frequently Asked Questions (FAQ)

Q: What is the difference between "Fireproof" and "Flame Retardant"?

A: Technically, "Fireproof" implies a material that will never burn (like Fiberglass or Concrete). "Flame Retardant" means the fabric resists burning and self-extinguishes once the fire source is removed. In the textile industry, we use these terms to describe materials that prevent fire spread.

Q: Which fabric is best for welding?

A: For heavy equipment protection, use Fiberglass or Oxidized PAN blankets. For welder's clothing (PPE), use FR Cotton or Leather alternatives, as they are breathable and shed sparks.

Q: Can I get a certificate for these fabrics?

A: Yes. All our products come with technical data sheets (TDS) and third-party test reports validating their compliance with specific standards (like UL, ISO, or NFPA). Please contact us for specific documentation.