IFR Modacrylic Fabrics: The Gold Standard for Multi-Risk Protection

IFR Modacrylic (Modified Acrylic) is a high-performance copolymer fiber designed specifically for inherent flame resistance. Unlike treated fabrics, the fire protection is part of the fiber's DNA and will never wash or wear out.

What sets Modacrylic apart is its incredible versatility. It is easily dyed into bright, fluorescent colors for

High Visibility safety gear, and it offers exceptional resistance to chemicals and electric arcs. Often blended with cotton or lyocell for enhanced comfort, Modacrylic fabrics provide a soft, non-synthetic feel while delivering robust protection against flash fires and electrical hazards.

Key Features

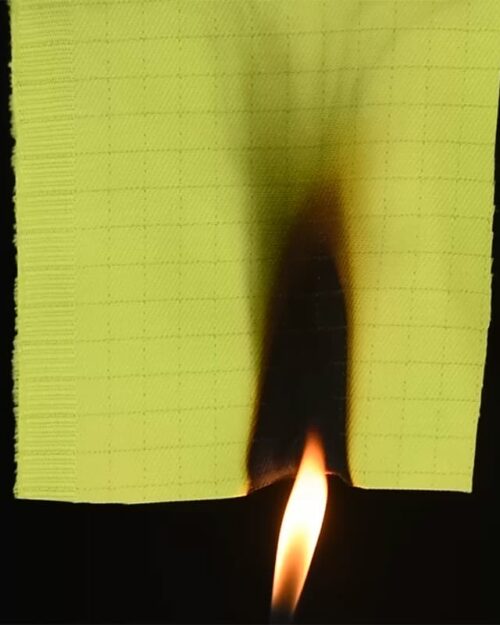

- Inherently Flame Retardant (IFR): The flame resistance is built into the molecular structure. It self-extinguishes immediately upon removal of the ignition source and does not melt or drip.

- High Visibility Capable: It is one of the few FR fibers that can be dyed into certified fluorescent Yellow and Orange, making it essential for roadside and railway safety.

- Arc Flash Protection: Excellent insulation properties make it a top choice for protecting against electrical arc thermal risks (Arc Rated).

- Chemical Resistance: highly resistant to acids, alkalis, and industrial solvents, offering durability in harsh petrochemical environments.

International Standards Compliance

Our Modacrylic fabrics are engineered to meet a wide range of global safety standards, often referred to as "Multi-Norm" compliance:

- NFPA 2112: Standard on Flame-Resistant Clothing for Protection of Industrial Personnel Against Short-Duration Thermal Exposures from Fire.

- ASTM F1506 / NFPA 70E: Standard specification for arc rated textile materials for electrical workers.

- EN ISO 20471: High visibility clothing (Modacrylic is ideal for meeting the color and luminance requirements).

- EN ISO 11612: Protective clothing to protect against heat and flame.

- EN 13034: Protection against liquid chemicals (Type 6).

Applications

| Sector |

Typical Use Cases |

Why Modacrylic? |

| Electric Utility |

Lineman Suits, Arc Flash Gear |

Superior arc thermal performance (ATPV/EBT) and comfort. |

| Road & Railway |

Hi-Vis Vests, Trackside Overalls |

The only way to achieve FR + Fluorescent Hi-Vis in one fabric. |

| Petrochemical |

Refinery Coveralls, Lab Coats |

Resists acid splashes and chemical corrosion while resisting fire. |

| General Industry |

Winter FR Jackets, Fleece |

Can be processed into warm fleece or fur-like textures easily. |

Frequently Asked Questions (FAQ)

Q: Is Modacrylic better than treated FR cotton?

A: For durability, yes. Since Modacrylic is inherently FR, you never have to worry about the protection washing out or being compromised by bleach or softeners, unlike some treated cottons.

Q: Why is Modacrylic often blended with cotton?

A: Blending Modacrylic with cotton or lyocell creates a "best of both worlds" fabric: you get the inherent safety and durability of Modacrylic combined with the moisture absorption and natural skin-feel of cotton.

Q: Does it melt?

A: Modacrylic does not melt or drip like standard acrylic or polyester. Upon exposure to flame, it chars and self-extinguishes, forming a protective barrier that prevents burns.