Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Abstract: This article provides a technical deep dive into Begoodtex’s newly developed Inherent Flame Retardant (IFR) Slub Fiber. By combining permanent flame retardancy with a unique “micro-crimp” physical structure, this material bridges the gap between industrial safety and aesthetic design, offering superior breathability and a natural texture while meeting rigorous fire safety standards.

Begoodtex IFR Slub Fiber is an advanced textile substrate that integrates Inherent Flame Retardancy with Biomimetic Artistry. It was engineered to disrupt the industrial stereotype of traditional fire-resistant fabrics, which are often characterized as smooth, rigid, and lacking breathability.

Unlike standard FR polyester, this product achieves a technological breakthrough in two dimensions:

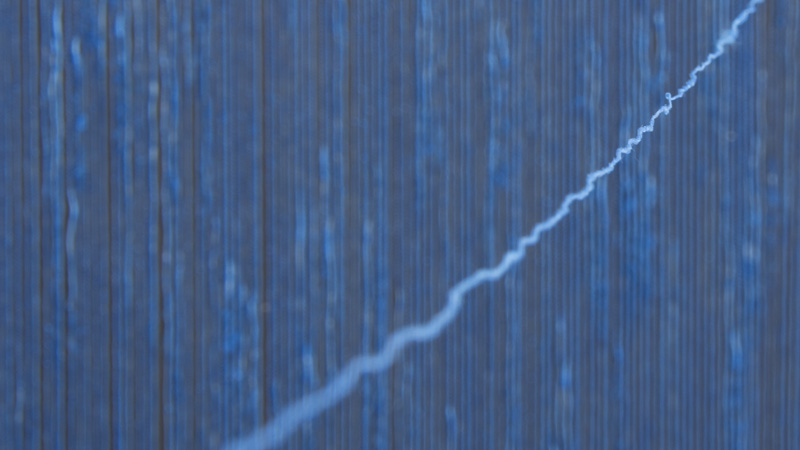

Microscopic analysis of the single yarn reveals that this fiber is not merely uneven in thickness; it exhibits a high-frequency wavy crimp.

Safety is the DNA of this product. In direct flame contact tests, the fiber demonstrates a superior defense mechanism:

Due to the “Slub” irregularities, the yarns cannot pack tightly against each other during weaving, naturally creating micro-air channels.

The introduction of this new material opens up entirely new possibilities for downstream product development:

| Application Field | Recommended Product | Technical Advantage |

|---|---|---|

| Industrial PPE | FR Gaiters / Overshoes | Leverages the “micro-crimp structure” for superior airflow, keeping feet dry while providing No Melt-Drip protection. |

| Specialized Workwear | Abrasion Resistant Patches | Utilizes the high friction coefficient of the slub surface to provide excellent anti-slip grip and durability. |

| Commercial Interiors | FR Curtains / Wall Coverings | Replaces expensive post-treated linen, achieving a B1-grade permanent fire rating with a “Natural Look” aesthetic. |

| Acoustic Solutions | Acoustic Panels | The irregular, crimped surface effectively diffuses sound waves, improving the acoustic quality of interior spaces. |

A: The fiber is designed to meet major international standards, including NFPA 701, EN ISO 11611/11612, and the Chinese GB 8624 B1 standard.

A: No. Although the appearance varies in thickness, we apply special twist reinforcement at the slub connection points during spinning. Furthermore, the micro-crimp structure aids in stress dispersion, ensuring physical strength meets industrial tear-resistance requirements.

A: The core advantage is Permanent Safety. Begoodtex IFR fibers derive their protection from their internal molecular structure. The protection does not wash out, and unlike coated fabrics, they do not drip when burned, making them safer and more eco-friendly over their lifecycle.