Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Water repellency is the ability of a fabric to resist surface wetting, characterized by the “Lotus Effect” where water droplets bead up and roll off the surface without being absorbed. In the textile industry, ISO 4920 and AATCC TM22 are the two most recognized global standards for measuring this performance via the Spray Test method, essential for outdoor gear, medical PPE, and industrial fabrics.

Textile water repellency, often referred to as “Spray Resistance,” is achieved by applying a Durable Water Repellent (DWR) finish to the fabric surface. This finish lowers the surface tension of the fibers, preventing water from spreading and wetting the material. Unlike waterproofing, which prevents penetration through the fabric, water repellency focuses strictly on the surface’s resistance to moisture absorption.

While ISO 4920 and AATCC TM22 utilize nearly identical testing apparatus and procedures, they are governed by different organizations and use different scoring scales. Both are used to evaluate the same physical phenomenon: the resistance of fabrics to surface wetting by water.

| Standard | Organization | Primary Markets | Grading Scale |

|---|---|---|---|

| ISO 4920 | International Organization for Standardization | Europe, Asia, International | Grade 1 – 5 |

| AATCC TM22 | American Association of Textile Chemists and Colorists | North America, US Brands | Score 0 – 100 |

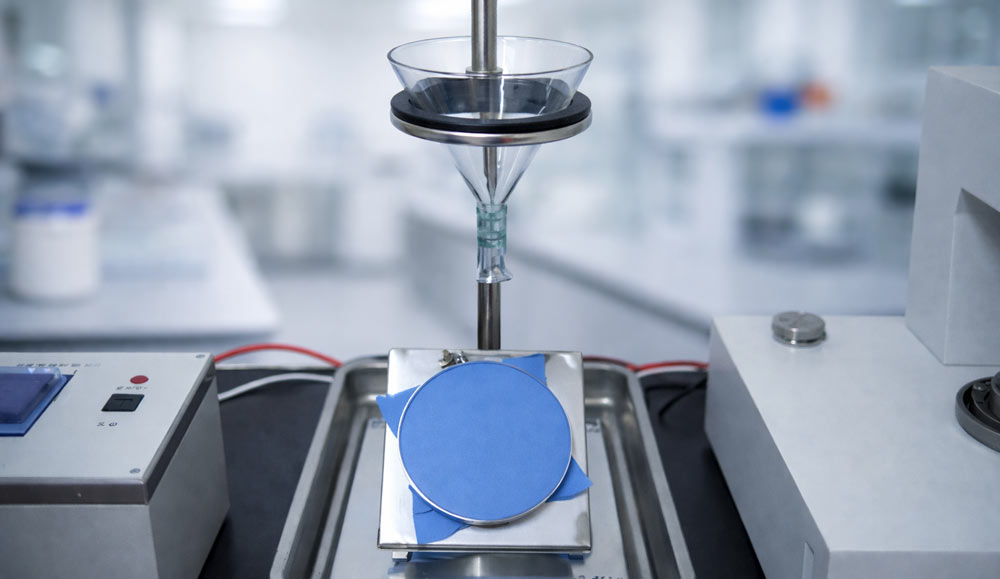

The Spray Test (Spray Method) simulates a controlled rainfall scenario to observe how a fabric sample reacts to surface contact with water. It is a rapid, cost-effective, and highly visual test that provides an immediate indication of a fabric’s DWR performance.

The results are determined by comparing the tested specimen against a Standard Spray Test Rating Chart. The ISO 1-5 scale and the AATCC 0-100 scale correspond directly to the degree of surface wetting observed.

| Visual Appearance | ISO 4920 Grade | AATCC 22 Score | Performance Level |

|---|---|---|---|

| No sticking or wetting of the upper surface. | Grade 5 | 100 | Excellent (Lotus Effect) |

| Slight random sticking or wetting of the upper surface. | Grade 4 | 90 | Good |

| Wetting of the upper surface at spray points. | Grade 3 | 80 | Satisfactory (Standard) |

| Partial wetting of the whole of the upper surface. | Grade 2 | 70 | Poor |

| Complete wetting of the entire upper surface. | Grade 1 | 50 / 0 | Fail |

The most common misconception in the industry is equating Water Repellency (ISO 4920) with Waterproofing (ISO 811). While repellency prevents the surface from getting “wet,” waterproofing prevents water from “leaking” through the fabric under pressure.

With global regulations (such as REACH and PFAS bans) phasing out traditional C8 and C6 fluorinated water repellents, the industry is transitioning to C0 (Fluorine-Free) DWR. While eco-friendly, C0 finishes traditionally struggle with oil repellency and wash durability. Advanced solutions like BEGOODTEX Eco-Dry utilize innovative molecular cross-linking to achieve AATCC 100/ISO 5 ratings initially, maintaining AATCC 80+ performance even after 20 industrial washes.

A: Yes, they are effectively equivalent. The testing equipment and methodology are identical. A result of “Score 90” in AATCC 22 is generally accepted as “Grade 4” in ISO 4920. Most labs report both values simultaneously.

A: This indicates that the DWR (Water Repellent) finish has degraded, a phenomenon known as “wetting out.” While the internal waterproof membrane may still prevent leaks, the saturated outer fabric prevents moisture vapor (sweat) from escaping, making you feel cold and damp.

A: DWR can often be reactivated by heat. After washing, tumble drying on a medium setting or light ironing (following care label instructions) can “re-align” the hydrophobic molecules on the surface, restoring the lotus effect.

A: Under the AAMI PB70 standard for medical PPE, the Spray Test (AATCC 22) is a mandatory requirement for Levels 1, 2, and 3. It ensures that fluids like blood or saline roll off the gown immediately upon contact, minimizing the window of time for potential fluid strike-through or contamination.