Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Visibility is the difference between safety and a serious accident. In industries like road construction, aviation, or logistics, being seen by a vehicle operator is the primary defense for a worker. However, not all bright vests are created equal. A “neon” vest bought from a local supermarket is not the same as professional-grade EN 20471 compliant workwear.

This guide explains the technicalities of the EN 20471 standard, how the material layers work, and how to select the correct protection level for your specific work environment.

EN 20471 is the international safety standard for High-Visibility Warning Clothing. It specifies the requirements for Personal Protective Equipment (PPE) capable of signaling the user’s presence visually. Whether it is bright sunshine, fog, or total darkness, this standard ensures that the wearer is conspicuous to operators of vehicles or other mechanized equipment.

Originally known as EN 471, the standard was updated to EN ISO 20471 in 2013 to harmonize it globally. It defines how much fluorescent material and retroreflective tape must be used and where it must be placed on the body to ensure “human shape” recognition from all angles.

The core goal of EN 20471 is simple: to make sure workers can be seen in any lighting condition, 24 hours a day, reducing the risk of collisions in hazardous environments.

To provide 24-hour protection, compliant clothing must use two distinct types of materials that work together. They are not interchangeable; they serve specific roles based on the light source.

This is the primary body fabric of the garment. Fluorescent fabrics absorb invisible ultraviolet (UV) light from the sun and re-emit it as visible light. This makes the fabric appear much brighter than normal colors, even in flat light, mist, or dusk. The standard allows three colors: Fluorescent Yellow, Orange-Red, and Red.

These are the silver strips or tapes applied on top of the background fabric. It uses glass bead or micro-prism technology to bounce light (like truck headlights) directly back to the source. Without these tapes, a worker is practically invisible at night, regardless of how bright the body fabric color is.

| Material Component | Role in Garment | Primary Function | Optimal Conditions |

|---|---|---|---|

| Fluorescent Fabric | Main Body / Base Layer | Daytime visibility | Fog, rain, sunlight |

| Retroreflective Tape | Applied Strips / Accents | Nighttime visibility | Darkness, headlights |

Compliance Tip: A garment is only EN 20471 certified if it contains both materials. A bright neon shirt without tapes, or a dark jacket with only tapes, will not pass the safety audit.

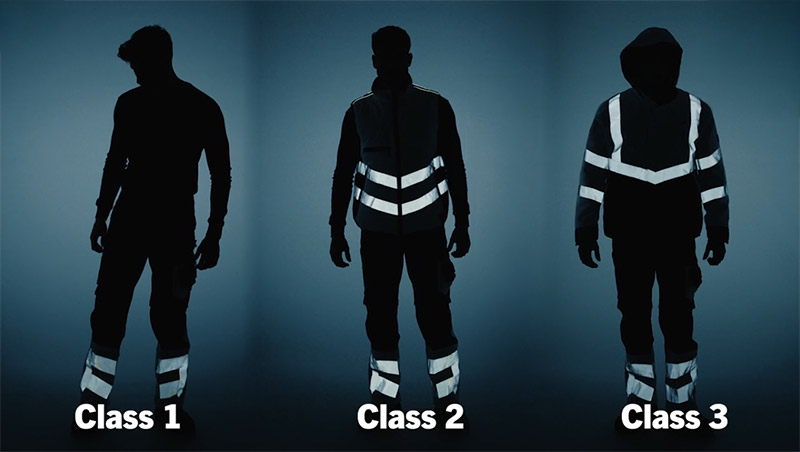

EN 20471 categorizes clothing into three classes based on the minimum surface area of visible material. The higher the class, the more visible the worker is to a driver.

| Requirement | Class 1 | Class 2 | Class 3 |

|---|---|---|---|

| Fluorescent Body Fabric | 0.14 m2 | 0.50 m2 | 0.80 m2 |

| Reflective Tape Area | 0.10 m2 | 0.13 m2 | 0.20 m2 |

Meeting the surface area requirement is not enough. EN 20471 strictly regulates the layout of the materials to ensure the worker is recognized as a human being rather than a stationary object.

The garment must be designed so that the wearer is visible from all angles (front, back, and sides). Key design details include:

The choice of base fabric impacts both compliance and wearer comfort. Since these garments are used in industrial settings, the material must withstand heavy use.

To meet these high standards, Begoodtex offers a range of professional fabrics that balance fluorescent colorfastness with exceptional durability, including options that integrate flame-retardant and anti-static properties. Their cotton-blend series further enhances breathability and moisture-wicking without sacrificing industrial-grade strength, ensuring long-lasting comfort in demanding environments.

While EN 20471 is the European and international standard, ANSI/ISEA 107 is the equivalent used in the United States. They share the same objective of protecting workers through visibility, but their testing methods for retroreflectivity and classification (Types vs. Classes) differ slightly. For global projects, it is essential to ensure the garment meets the specific standard required by local law.

EN 20471 is a life-saving technical standard that balances fabric science with strategic design. To ensure total compliance:

Yellow is technically brighter (higher luminance), but orange provides better contrast in green environments like forests or fields. Both are fully compliant.

No. For EN 20471 compliance, you must have both the fluorescent body fabric for daytime and reflective tapes for nighttime.

Check the care label. Most garments are certified for 25 to 50 washes. Beyond this, the reflective tape’s performance may drop below the safety threshold.

The garment should be replaced. Cracks indicate that the glass beads or prisms are damaged, which significantly reduces nighttime visibility.

Yes. EN ISO 20471 is the modern international version with stricter requirements for recognizing the human shape.