Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

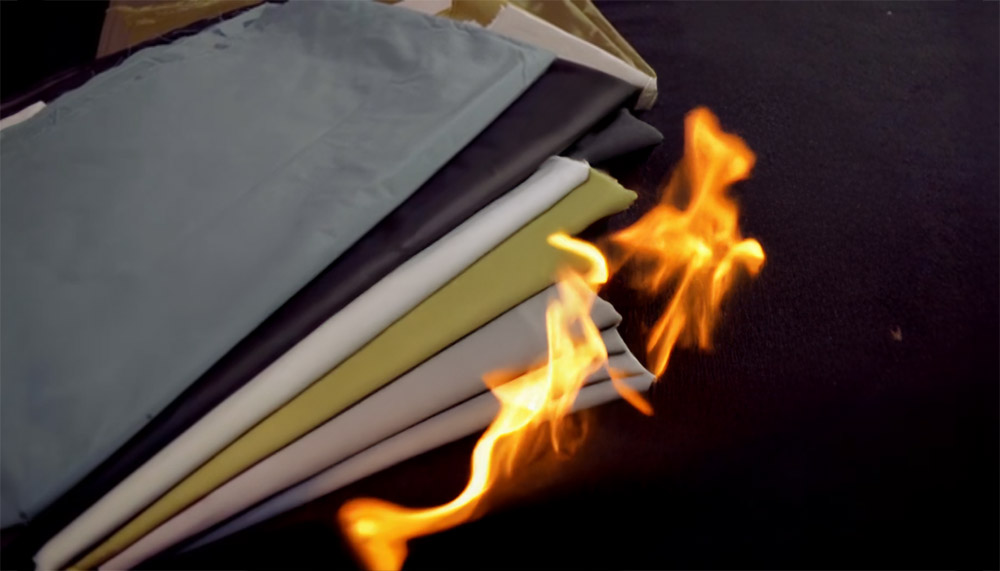

Nylon fabric is favored for its durability and versatility, but when it comes to fire safety, it hides a critical question. Is it flammable or safe? The answer is far more complex than a simple “yes” or “no.” It involves the material’s chemical properties, a hazardous molten drip phenomenon, and advanced flame-retardant technologies. This authoritative guide will deconstruct nylon’s true burning behavior, its potential risks, and how to select safe, certified products to help you make an informed safety decision.

Nylon fabric, chemically known as Polyamide (PA), is a high-performance synthetic fiber textile. It is renowned for its exceptional strength, excellent abrasion resistance, high elasticity, and light weight, making it widely used in apparel (especially sportswear and lingerie), industrial goods (like ropes and seatbelts), outdoor gear (like tents and backpacks), and home textiles.

Nylon fabric is flammable, but its burning behavior is very distinct. Unlike natural fibers such as cotton or linen, untreated regular nylon (like Nylon 6 or Nylon 66) will quickly melt, shrink, and pull away from the flame source, exhibiting a degree of “self-extinguishing” behavior. However, if the heat source persists, it will burn and produce hot molten drips, which pose a serious safety hazard.

Nylon is a thermoplastic polymer, and its hallmark burning characteristic is the “melt drip.” When it approaches a flame, it doesn’t ignite directly like cotton. Instead, it first reaches its melting point (approx. 220°C for Nylon 6, 260°C for Nylon 66) and melts into a viscous liquid. This melting action causes it to shrink from the flame, but continuous heating will cause it to burn and drip.

The main risk from burning nylon is not from rapid flame spread, but from the hot molten drips it produces. These drips are extremely hot and can cause severe, deep burns if they land on skin, as they adhere and continue to release heat. Simultaneously, these hot drips can ignite other combustible materials below (like carpets or furniture), starting secondary fires.

To better understand nylon’s unique properties, the table below compares the behavior of different fibers in a flame:

| Fiber Type | Near Flame | In Flame | After Flame | Odor | Residue |

|---|---|---|---|---|---|

| Nylon | Melts and shrinks | Melts and burns slowly | Usually self-extinguishes | Like celery or plastic | Hard, black, irregular bead |

| Polyester | Melts and shrinks | Melts and burns slowly, with black smoke | Usually self-extinguishes | Slightly sweet, chemical odor | Hard, black, round bead |

| Cotton | Does not melt, ignites directly | Burns quickly with a yellow flame | Continues to burn (afterglow) | Like burning paper | Soft, gray or black ash |

| Wool | Curls away from flame | Burns slowly, chars | Usually self-extinguishes | Like burning hair | Brittle, black, hollow bead |

As a polyamide polymer, nylon’s molecular chains are primarily composed of carbon, hydrogen, oxygen, and nitrogen atoms. When subjected to sufficiently high heat (its ignition temperature is around 420°C – 530°C), the chemical bonds in the molecular chains break, causing thermal degradation. This process releases flammable hydrocarbon gases, which mix with oxygen in the air and are ignited by the heat source, thus sustaining the combustion reaction.

To address nylon’s flammability and melt-drip risk, “Flame Retardant (FR) treatment” technologies are widely used in the industry. The goal of FR treatment is not to make nylon completely fireproof, but to chemically or physically inhibit the combustion process, slow the flame spread, and reduce or eliminate molten drips. This allows it to self-extinguish quickly once the flame source is removed, buying valuable time for escape and firefighting.

Inherently Flame Retardant (IFR) is a method that solves the problem at the fiber’s source. Through copolymerization or co-blending spinning techniques, flame-retardant chemical groups (like phosphorus or nitrogen compounds) are introduced into nylon’s molecular chain during the polymerization stage. This makes the FR property an intrinsic part of the fiber, making it permanent. It will not wash out or wear away with repeated laundering or daily use.

Topical FR (also called a fabric finish) is applied after the nylon fabric has been woven. Liquid flame retardants are applied to the fabric’s surface or permeated into the fiber gaps through dyeing and finishing processes like padding, coating, or spraying. This method is relatively low-cost and the process is flexible. However, its FR properties are typically non-permanent and may diminish or be lost over time with washing, friction, and age.

| Characteristic | Inherently FR (IFR) | Topical / Post-Treatment FR |

|---|---|---|

| FR Principle | FR agents are copolymerized into the fiber’s molecular chain | FR agents are chemically or physically bonded to the fabric surface |

| Durability | Permanent, withstands washing and dry cleaning | Limited, diminishes with washing |

| Hand-feel & Appearance | Usually softer, does not affect original texture | May slightly stiffen the hand-feel or have a “coated” texture |

| Use Cases | Hotels, hospitals, transportation, and high-end apparel requiring high durability | Decorative applications with limited budgets and low washing frequency |

| Cost | Higher | Relatively lower |

While FR treatment improves nylon’s safety, it almost inevitably affects the material’s other properties. The extent of the impact depends on the type of flame retardant used, the amount added, and the treatment process. The most significant effects are typically seen in mechanical properties, hand-feel, and durability.

Filler-type or blended flame retardants (like inorganic fillers) may increase the material’s rigidity but often reduce its original toughness and impact strength. The compatibility between the flame retardant and the nylon matrix is crucial; if dispersion is poor or compatibility is low, it will lead to a significant decline in mechanical properties, even causing brittleness.

The surface coating method (post-treatment) is most likely to affect the fabric’s original hand-feel, potentially making it stiffer, creating a “coated” feeling, and possibly blocking the fabric’s pores, which reduces breathability. In contrast, IFR and high-quality immersion processes have a relatively smaller impact on hand-feel and better preserve nylon’s soft texture.

Durability is the key differentiator for FR technologies. The FR performance of Inherently Flame Retardant (IFR) nylon is part of the fiber and has excellent washability, able to withstand dozens or even hundreds of industrial launderings. In contrast, post-treatment FR (especially simple immersion methods) has poor washability, as the flame retardant can easily be washed out, leading to a loss of FR effectiveness.

FR nylon’s stability in high-temperature environments far exceeds that of regular nylon, but its specific performance depends on the FR system used. Regular nylon will soften and deform rapidly as it approaches its melting point (approx. 220°C – 260°C). High-performance FR nylon (especially those modified by copolymerization or high-performance fillers) is designed to maintain structural integrity at high temperatures, delay thermal decomposition, and release substances that inhibit combustion, thus demonstrating much higher thermal stability in a fire.

Consumers and buyers should identify FR nylon by checking product labels, certifications, and technical specification sheets, rather than performing dangerous burn tests themselves. Looking for professional third-party certification is the most reliable and safest way to assess its FR performance.

FR standards are the “passports” for fabric safety. Different applications have different mandatory standards:

When purchasing, you should proactively request the following information from the supplier to ensure safety and compliance:

Due to its safety and durability, FR nylon is widely used in fields with mandatory fire safety requirements:

Want to understand the differences in flammability, flame-resistant ratings, and LOI (Limiting Oxygen Index) among various fibers? We have compiled a list of related professional articles to help you quickly determine if a material is safe and suitable for use as a flame-resistant fabric, click the link below to view quickly:

A: No. “Flame Retardant” means the material has been treated to inhibit or slow the spread of flames and to self-extinguish once the heat source is removed. The goal is to provide time for escape. “Fireproof” or “Non-combustible” means the material (like glass or steel) will not burn at all. The vast majority of textiles can only be made “flame retardant,” not “fireproof.”

A: Yes, qualified FR nylon is safe. Reputable manufacturers use eco-friendly and safety-certified flame retardants, such as those compliant with Oeko-Tex Standard 100. This certification ensures that chemical residues are within safe limits and harmless to human health. Choosing products with such certifications ensures skin safety.

A: It depends on the FR type. Inherently Flame Retardant (IFR) nylon’s properties are permanent and will not be affected by repeated washing or dry cleaning. Topical/Post-Treatment (FR) fabric may lose its effectiveness over time with washing. Therefore, you must follow the manufacturer’s care and washing instructions to maintain its flame-retardant properties.

A: They are very similar. Both are thermoplastic fibers that will melt, shrink, drip, and typically self-extinguish after the flame is removed. The main difference is the odor and residue: nylon smells like celery or plastic and leaves a hard, black, irregular bead; polyester has a slightly sweet, chemical smell and leaves a hard, black, round bead.

A: Because regular nylon melts quickly when heated and can produce hot, molten drips. If these molten drips adhere to the skin, they can cause severe deep burns, which are often worse than a flame burn. Therefore, you should avoid wearing regular nylon or polyester clothing when barbecuing, near a campfire, or welding, and opt for natural fibers like cotton or wool instead.