The core reason aramid (Aramid) does not burn lies in its unique “Inherent Flame Resistant” (IFR) property. This originates from the aromatic ring structure in its molecular backbone, which has extremely high bond energy. This rigid structure is exceptionally stable at high temperatures, causing it to not melt or drip (it has no melting point). When exposed to flame, the aramid fiber surface rapidly dehydrates and forms a dense char layer, which effectively insulates against heat and blocks oxygen, thus interrupting the combustion chain reaction.

This permanent safety, derived from the material’s DNA, is the fundamental difference between aramid and common “FR-treated” materials (like treated cotton). To fully understand aramid’s position and advantages within the high-performance fiber family, please read our authoritative aggregate guide: Aramid Fabric Explained: A Comprehensive Guide from Molecular Structure to Ultimate Fire Protection.

Aramid’s “Inherent Safety”: A Look at its Molecular Structure

To understand aramid’s flame resistance, one must look deep into its molecular level. The secret of Aramid (Aromatic Polyamide) is hidden in its chemical name.

1. Aromatic Rings: The Cornerstone of Stability

Aramid’s molecular backbone is composed of numerous rigid aromatic rings (i.e., benzene rings). The benzene ring is a highly stable chemical structure with extremely high carbon-carbon bond energy. Tremendous energy is required to break these bonds under high heat or flame. In contrast, the aliphatic chains (-CH₂-CH₂-) of common polymers (like polyester or nylon) have lower bond energy and break easily at high temperatures, producing flammable gases.

2. Amide Bonds: The Rigid Connection

Connecting these aromatic rings are strong amide bonds (-CONH-). These bonds provide a highly regular and rigid connection, making the entire polymer chain difficult to move or curl. This rigid structure further enhances the material’s overall thermal stability.

Core Decryption: Aramid’s Four Synergistic Flame Resistant Mechanisms

When aramid fiber comes into contact with flame, it doesn’t “resist” combustion; it “terminates” it through a series of complex physical and chemical reactions. This process relies on four major mechanisms:

1. Extremely High Decomposition Temperature (Heat Resistance)

Ordinary fibers (like cotton) begin to decompose and burn at around 250°C. Aramid’s thermal decomposition temperature is extremely high. The specific structures of meta-aramid and para-aramid differ slightly in temperature resistance, but both far exceed common fibers:

- Meta-Aramid: Decomposition temperature is around 370°C.

- Para-Aramid: Decomposition temperature can exceed 500°C.

This means that in a fire, aramid can maintain its structural integrity for a longer period, buying precious time for evacuation or operations.

2. No Melt, No Drip (A Critical Safety Feature)

Many common synthetic fibers (like polyester and nylon) melt quickly when heated, forming scalding molten droplets. These droplets not only cause severe skin burns but also fall onto other surfaces, causing “secondary ignition” and accelerating the fire’s spread. Aramid has no melting point; it only carbonizes at high temperatures and never drips, fundamentally eliminating this safety hazard.

3. Carbonization Layer Protection (The Core Barrier)

This is aramid’s most critical fire-protection mechanism. When the flame touches the fiber surface, the aramid rapidly undergoes dehydration and cross-linking reactions, forming a dense, insulating black char layer. This char layer acts as a “fire shield,” providing three types of protection simultaneously:

- Blocks Oxygen: The dense carbon layer prevents oxygen from the air from penetrating the fiber’s interior, cutting off the oxidative reaction needed for combustion.

- Insulates Heat: The char layer has excellent thermal insulation properties, slowing the transfer of external heat to the inner fibers and protecting the internal structure.

- Suppresses Flammable Gases: It prevents the small amounts of flammable gases produced by thermal decomposition inside the fiber from escaping and feeding the fire.

When the flame source is removed, the combustion chain reaction is immediately broken due to the lack of sufficient heat and oxygen, and the flame quickly extinguishes.

4. Inert Decomposition Products (Low Smoke, Non-Toxic)

During thermal decomposition, aramid primarily produces inert gases such as water vapor, carbon dioxide, and nitrogen. These gases do not support combustion and, in fact, help to dilute the oxygen concentration in the flame zone. More importantly, aramid is a halogen-free material and does not release highly toxic dioxins or corrosive gases, which gives it excellent environmental and safety characteristics.

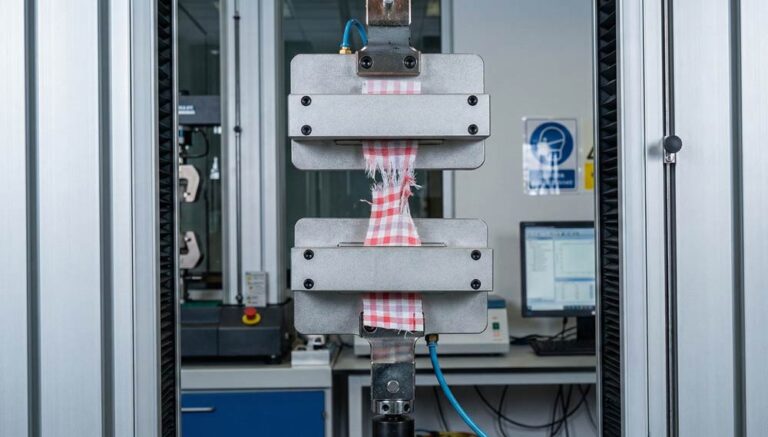

Performance Comparison: Aramid vs. Common Fibers’ Flammability

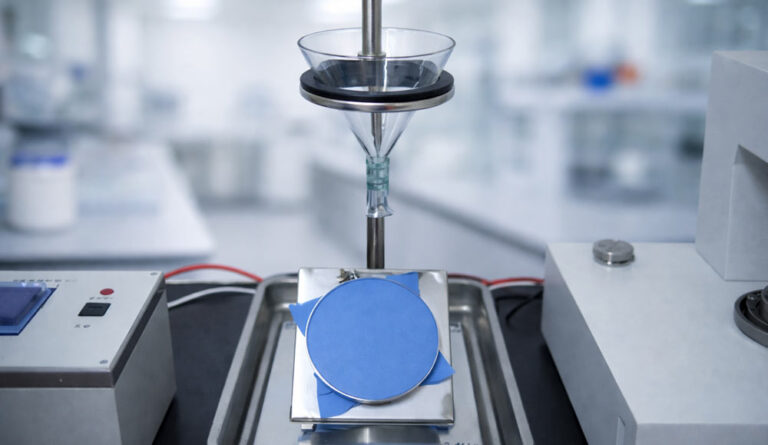

A key indicator for measuring a material’s flammability is the Limited Oxygen Index (LOI), which is the minimum concentration of oxygen required to sustain combustion (the air contains about 21% oxygen). The higher the LOI, the more difficult the material is to burn.

| Fiber Material | Limited Oxygen Index (LOI) % | Burning Characteristics | FR Type |

|---|---|---|---|

| Aramid | 28 – 31 | Carbonizes, No Drip, Self-extinguishing | Inherent FR (IFR) |

| Regular Cotton | 18 – 20 | Flammable, continuous burning, afterglow | Non-FR |

| Polyester | 20 – 22 | Flammable, melts and drips, fuels fire | Non-FR |

| FR-Treated Cotton | 28 – 32 | Can self-extinguish, but char breaks open | Treated FR |

The table shows that aramid’s LOI is similar to high-quality FR-treated cotton, but aramid’s advantage lies in its “inherent” nature, far surpassing the latter in durability and char strength.

Authoritative Verification: Which Standards Prove Aramid’s Performance?

Aramid fabric’s FR performance must pass the world’s most stringent fire safety standards to be used in various industrial, electrical, and firefighting applications. Aramid fabrics typically pass the following fabric fire standards:

- NFPA 2112: Standard for flash fire protection for industrial personnel.

- EN 11612: European standard for protective clothing against heat and flame.

- NFPA 701: Vertical flame test for fire curtains in public spaces.

- ASTM D6413: Standard vertical flame test method to measure char length, afterflame, and afterglow.

Conclusion: Why Choose Aramid?

Aramid’s resistance to burning is the result of its highly stable aromatic chemical structure, high decomposition temperature, non-drip properties, and the critical char layer protection mechanism all working in concert. This makes it the ultimate safety choice for applications like firefighting suits, arc flash protection, aerospace interiors, and industrial insulation.

About Aramid Fabric Flame Retardancy Topics

To help you quickly locate the information you need, we have summarized all knowledge about aramid into the following seven topics. You can browse the “Key Points” for a quick summary or click the title to read the full in-depth guide.

| Category | Topic Guide | Key Points |

|---|---|---|

| Outline | Aramid Fabric Explained | A Comprehensive Guide to Aramid Fabrics: From Molecular Structure to Ultimate Fireproof Performance |

| Mechanism | Why Is Aramid Flame Resistant? | Core Principle: Aramid relies on high-bond-energy aromatic ring structures to resist heat. It forms a protective char layer when burning, blocking oxygen and heat, and does not melt or drip, achieving self-extinguishing. |

| Structure | What Is the Difference Between Aramid 1313 and 1414? | Core Difference: 1313 (Meta-Aramid) has a flexible structure, excelling in heat resistance and flame retardancy (e.g., firefighting suits). 1414 (Para-Aramid) has a rigid structure, renowned for ultra-high strength (e.g., body armor). |

| Comparison | What Are the Differences Between Aramid and FR Cotton Fabric? | Core Difference: Aramid is inherently flame-resistant (permanent, no-drip), while FR cotton is chemically treated (performance degrades with washing). Aramid’s protection in extreme heat is far superior. |

| Standards | Which International Flame Retardant Standards Does Aramid Pass? | Authoritative Certification: Aramid fabric can pass the world’s strictest FR tests, such as NFPA 2112 for apparel, EN 11612 (Europe), and NFPA 701 / DIN 4102-B1 for public spaces. |

| Applications | What Are the Typical Applications for Aramid Fabric? | Application Fields: Due to its high performance, aramid is widely used in firefighting suits, aerospace interiors, electric arc protection, industrial heat insulation, and fire curtains. |

| Eco-Safety | Is Aramid Eco-Friendly and Non-Toxic? | Safety & Eco-Friendliness: Aramid is a halogen-free material with low smoke toxicity and no dioxin release. It can be OEKO-TEX® Standard 100 certified, proving it is safe for human skin. |

| Products | What Are the Aramid Product Classifications? | Product System: Aramid products are categorized into four main types: Aramid Fibers (raw material), Aramid Yarns (intermediary), Aramid Fabrics (end-product), and Deep-Processed Products (e.g., aramid paper, pulp). |

FAQ

What does “Inherent Flame Resistant” (IFR) mean?

Inherent Flame Resistant means the FR property is built into the fiber’s molecular structure (like aramid’s aromatic rings). It’s not a chemical treatment, so the protection is permanent and won’t wash or wear out.

How is Inherent Flame Resistant aramid different from FR-treated cotton?

Aramid’s Inherent Flame Resistant nature comes from its DNA, causing it to char and not melt or drip. FR-treated cotton relies on an added chemical finish, which can degrade over time with washing, and its char strength is typically weaker.

How does aramid’s Inherent Flame Resistant mechanism protect you?

When exposed to flame, the Inherent Flame Resistant fiber reacts instantly. It doesn’t melt or drip (preventing secondary burns) and forms a thick, insulating char layer that blocks heat and cuts off oxygen, stopping the fire.