The Aramid (Aramid) product system is extensive and can be divided into four main categories based on form and function: Aramid Fibers (industrial raw materials, e.g., dyeable fiber, high-tenacity fiber), Aramid Yarns (textile intermediaries, e.g., meta-aramid yarn, para-aramid yarn, colored yarn), Aramid End-Products (e.g., aramid fabric, webbing), and Deep-Processed Aramid Products (e.g., aramid pulp, short-cut fiber, and aramid paper).

This diverse range of product forms allows aramid to meet complex demands from basic protection to cutting-edge industry. To fully understand aramid’s principles, products, standards, and uses, please read our authoritative aggregate guide: Aramid Fabric Explained: A Comprehensive Guide from Molecular Structure to Ultimate Fire Protection.

I. Aramid Fibers – Industrial Raw Material

Fiber is the starting point of the aramid industry chain and is divided into multiple forms based on different performance needs:

1. Staple Fibers for Spinning

- Dyeable Aramid Fiber: This fiber is modified to have good spinnability, a soft hand-feel, and a bright luster. It is suitable for sewing threads, protective clothing, and high-temperature filtration materials where color is required.

- High Tenacity Spinnable Fiber: Possesses excellent temperature resistance and flame retardancy, with high fiber strength and crystallinity. It is suitable for industrial textiles, high-strength base fabrics, and acoustic applications.

- Dope-Dyed (Solution-Dyed) Fiber: Color is added before spinning, resulting in a full range of colors and high color fastness. The final product is safer and more eco-friendly, with high strength, and is suitable for all types of protective clothing and FR decorations.

- Industrial Non-woven Aramid Fiber: Features excellent temperature resistance and flame retardancy, serving as the raw material for industrial high-temperature conveyor belts, baghouse filter bags, and other non-woven products.

2. Aramid Filament

Aramid filament offers advantages like temperature resistance, flame retardancy, high strength, and bright luster. It is widely used in textile processing, rubber reinforcement materials (like hoses), other industrial fields, and protective clothing.

II. Deep-Processed Aramid Products

These products are based on the further processing of aramid fibers to meet specific industrial demands.

1. Short-Cut Aramid Fiber

This is a high-strength, safe, and eco-friendly short fiber. It is primarily used as a reinforcement material, suitable for manufacturing aramid paper, plastic reinforcement, friction materials (like brake pads), and various composite materials.

2. Aramid Pulp

Aramid pulp is an ultra-short fiber in a highly fibrillated (paper-pulp-like) form. It is mainly used as a specialty additive and is a core raw material for making aramid paper.

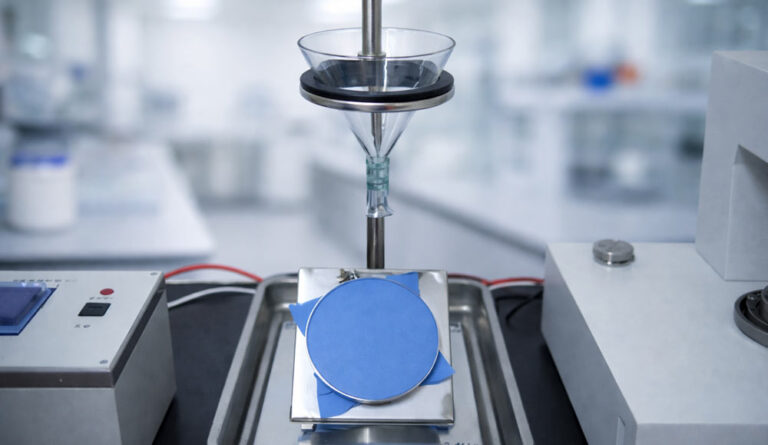

3. Meta-Aramid Paper

Aramid paper (made primarily from meta-aramid) is a specialty insulation material. It has high mechanical strength, high dielectric strength (insulation), flexibility, and resilience. Thanks to its excellent heat resistance and insulating effect, it is widely used in industrial applications requiring electrical insulation, such as motors and transformers.

III. Aramid Yarns

Yarns are intermediate products made by spinning aramid fibers. They are the foundation for weaving fabrics and sewing garments.

1. Aramid (Meta) Blended Yarns

These are the most common yarns for protective apparel, with various blends to balance performance. These blends leverage the respective advantages of meta-aramid and para-aramid:

- 100% Meta-Aramid: White in color, focusing on heat resistance and flame retardancy.

- 95% Meta-Aramid + 5% Para-Aramid: A small amount of para-aramid is blended in to significantly increase the yarn’s strength.

- 93% Meta-Aramid + 5% Para-Aramid + 2% Anti-Static Fiber: Adds anti-static functionality while increasing strength, suitable for environments with static-control requirements.

These yarns are mainly used for making protective apparel, zipper tapes, and knitted underwear.

2. Colored Yarns

Colored yarns are made via two processes:

- Dyed Yarn: Spun from dyeable fibers and then dyed, offering vibrant colors and excellent mechanical properties.

- Dope-Dyed Yarn: Spun from solution-dyed fibers, offering a full range of colors, extremely high color fastness, and good strength.

Both are suitable for protective apparel, sewing thread, and flame-retardant decorations.

3. Para-Aramid Yarn

This is a specialty yarn focused on strength. It possesses a superior combination of high strength, high modulus, abrasion resistance, radiation resistance, flame retardancy, and electrical insulation. Its applications are primarily in cut/stab protection (like gloves) and high-temperature resistance.

4. Fire Retardant Sewing Thread

This aramid thread is specifically designed for sewing protective apparel. It is resistant to chemicals, high temperatures (retains 70% of its strength after 1000 hours at 260°C), does not melt or drip, and carbonizes above 370°C without releasing harmful gases. Its FR principle is consistent with aramid fabric; refer to aramid’s combustion mechanism.

IV. Aramid End-Products

This is the most common form of aramid products, used directly to make finished goods.

1. Aramid Fabric

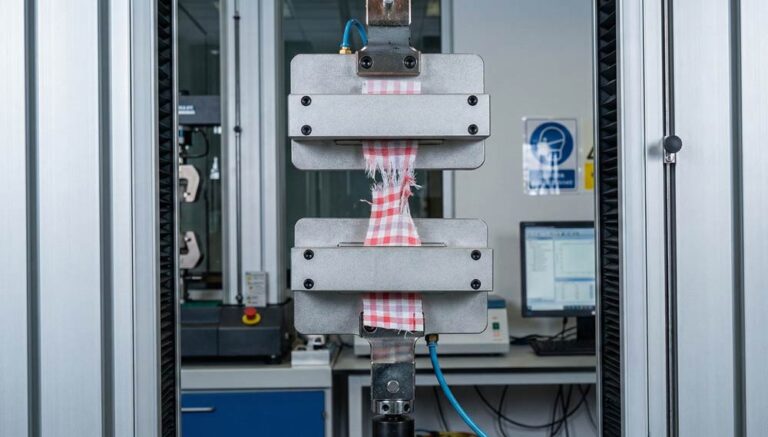

Aramid fabric integrates all the advantages of aramid fibers, including high tensile strength, high modulus, low elongation, chemical resistance, high-temperature resistance, and it is non-combustible, non-melting, and only carbonizes. Its performance must be certified by strict international flame-retardant standards.

Its applications are extremely broad, including furnace workwear, arc flash suits, firefighting gear, military combat suits, and flight suits.

2. Webbing

Aramid webbing is a high-strength, cut-resistant, abrasion-resistant, and high-temperature-resistant specialty textile. It features ultra-high tensile strength, ultra-low elongation, and high modulus.

It is suitable for military, firefighting equipment (like safety harnesses), special lifting/hoisting straps, industrial safety, and other high-demand fields.

About Aramid Fabric Flame Retardancy Topics

To help you quickly locate the information you need, we have summarized all knowledge about aramid into the following seven topics. You can browse the “Key Points” for a quick summary or click the title to read the full in-depth guide.

| Category | Topic Guide | Key Points |

|---|---|---|

| Outline | Aramid Fabric Explained | A Comprehensive Guide to Aramid Fabrics: From Molecular Structure to Ultimate Fireproof Performance |

| Mechanism | Why Is Aramid Flame Resistant? | Core Principle: Aramid relies on high-bond-energy aromatic ring structures to resist heat. It forms a protective char layer when burning, blocking oxygen and heat, and does not melt or drip, achieving self-extinguishing. |

| Structure | What Is the Difference Between Aramid 1313 and 1414? | Core Difference: 1313 (Meta-Aramid) has a flexible structure, excelling in heat resistance and flame retardancy (e.g., firefighting suits). 1414 (Para-Aramid) has a rigid structure, renowned for ultra-high strength (e.g., body armor). |

| Comparison | What Are the Differences Between Aramid and FR Cotton Fabric? | Core Difference: Aramid is inherently flame-resistant (permanent, no-drip), while FR cotton is chemically treated (performance degrades with washing). Aramid’s protection in extreme heat is far superior. |

| Standards | Which International Flame Retardant Standards Does Aramid Pass? | Authoritative Certification: Aramid fabric can pass the world’s strictest FR tests, such as NFPA 2112 for apparel, EN 11612 (Europe), and NFPA 701 / DIN 4102-B1 for public spaces. |

| Applications | What Are the Typical Applications for Aramid Fabric? | Application Fields: Due to its high performance, aramid is widely used in firefighting suits, aerospace interiors, electric arc protection, industrial heat insulation, and fire curtains. |

| Eco-Safety | Is Aramid Eco-Friendly and Non-Toxic? | Safety & Eco-Friendliness: Aramid is a halogen-free material with low smoke toxicity and no dioxin release. It can be OEKO-TEX® Standard 100 certified, proving it is safe for human skin. |

| Products | What Are the Aramid Product Classifications? | Product System: Aramid products are categorized into four main types: Aramid Fibers (raw material), Aramid Yarns (intermediary), Aramid Fabrics (end-product), and Deep-Processed Products (e.g., aramid paper, pulp). |

FAQ About Aramid Products

Q1: Are aramid products only available in yellow?

A: No. While the natural color of para-aramid (1414) is a pale yellow, the natural color of meta-aramid (1313) is white. Furthermore, aramid has specialized “dyeable fibers,” “solution-dyed fibers,” and “colored yarns,” which can provide a wide range of colors including black, red, blue, orange, and more.

Q2: What is the difference between aramid pulp and short-cut fiber?

A: Both are short-fiber forms used for reprocessing, but their form and use differ. Short-cut aramid fiber has a more regular length and is used for plastic reinforcement, friction materials, and composites. Aramid pulp is an ultra-short, “highly fibrillated” fiber, is fluffier in form, and is primarily used as a specialty additive for papermaking (aramid paper).

Q3: How do meta-aramid and para-aramid differ in final products?

A: Their products have different focuses. Meta-aramid (1313) products (like aramid paper, 100% meta-aramid yarn) focus on high-temperature resistance, flame retardancy, and electrical insulation. Para-aramid (1414) products (like para-aramid yarn) focus on high strength, high modulus, and cut/stab resistance. In blended yarns, 5% para-aramid is added specifically to increase strength.