Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

Get in touch

Thank you for reaching out! Please tell us more about your needs — our expert team will get back to you within 24 hours.

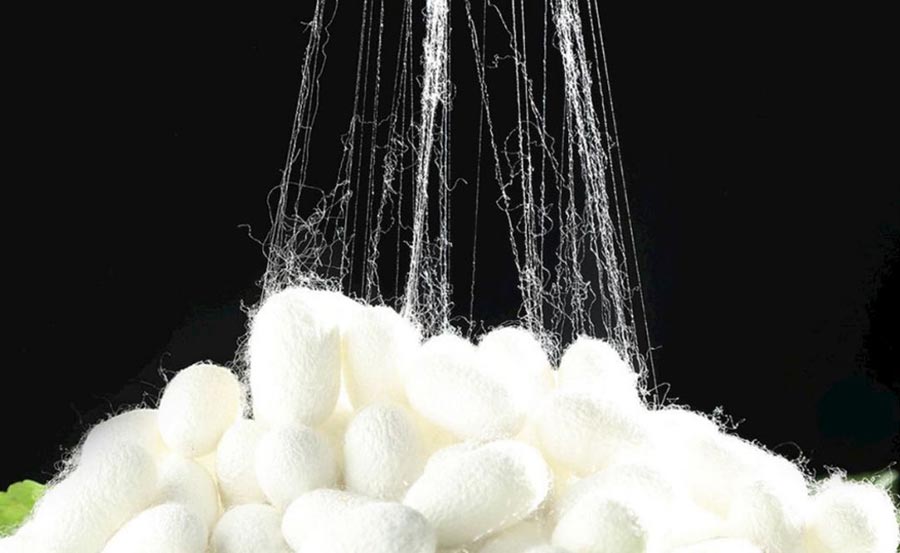

Silk, a natural protein fiber derived from silkworm cocoons, is renowned for its unique elegant luster, soft touch, and excellent moisture-wicking properties. It is widely used in high fashion, intimate apparel, and luxury home textiles. However, regarding safety performance, a core question always remains: Is silk flammable? Is it suitable for all decorative applications?

This article will revolve around this central question, providing a professional analysis from multiple perspectives including chemical structure, burning mechanisms, and comparative testing. It will also explain how its flammability limits its specific uses.

Silk is a flammable fiber. It does not belong to the category of non-flammable or flame-retardant fabrics. However, its burning speed is moderate to slow, distinguishing it from cotton or viscose (which are highly flammable) and wool (which is flame-resistant).

When silk encounters a flame, its typical behavior is:

The reason silk burns stems from its natural chemical composition. Silk’s main component is Fibroin, a type of animal protein fiber. Its molecular structure primarily contains Carbon (C), Hydrogen (H), Oxygen (O), and Nitrogen (N).

Although the nitrogen it contains makes it slightly more fire-resistant than cotton or viscose fibers, it is still flammable. Protein fibers undergo the following decomposition mechanism when heated:

The Limiting Oxygen Index (LOI) is a crucial scientific metric for determining a fiber’s flammability. It refers to the minimum concentration of oxygen in an oxygen-nitrogen mixture required to support sustained combustion of the material. The higher the LOI value, the more difficult it is to burn.

Silk’s LOI is approximately 24–25. According to industry standards, any fiber with an LOI below 26 is not considered “flame-resistant.” Therefore, silk is clearly classified as a flammable material.

| Fiber Type | LOI (Approx. Range) | Flammability |

|---|---|---|

| Cotton | 18–20 | Highly Flammable |

| Viscose | 19–20 | Highly Flammable |

| Polyester (PET) | 20–22 | Flammable, Melts |

| Silk | 24–25 | Flammable, burns slowly |

| Wool | 25–26 | Flame-Resistant, self-extinguishing |

| Modacrylic / Aramid | 28–32 | Flame Retardant (IFR) |

Silk’s burning characteristics are very unique, especially when compared to fabrics like cotton and polyester. The results of a manual burn test are very clear.

| Fabric | Flammability | Burning Characteristics |

|---|---|---|

| Silk | Flammable (Medium) | Curls away from flame, small flame, burnt hair odor, no melting/dripping, leaves a black, brittle char. |

| Cotton | Highly Flammable | Burns quickly with a large flame, leaves a soft, gray ash. |

| Viscose | Highly Flammable | Burns even faster than cotton. |

| Polyester | Flammable | Melts and drips, shrinks severely. |

| Nylon | Flammable | Melts and drips at low temperatures. |

| Wool | Flame-Resistant | High LOI, does not easily support combustion. |

Silk’s flammability is one of its inherent drawbacks, alongside other weaknesses like poor light resistance (yellowing) and reduced wet strength (cannot be machine washed). It is this safety characteristic that strictly limits silk’s range of applications.

Silk’s softness, skin-friendliness, breathability, and luxurious feel make it a top choice for apparel and home textiles.

In these domestic applications, its flammability is considered an acceptable risk, but users must take care to keep it away from open flames (like candles or fireplaces).

Because it is flammable and cannot pass strict fire codes, silk is severely restricted from use in public and commercial spaces that have mandatory fire safety requirements.

No. Natural silk cannot pass the vast majority of international commercial or contract textile fire standards. For example:

Theoretically, silk can undergo a flame-retardant (FR) finishing treatment, but this is very rare in industry practice because it has numerous limitations:

Although silk is a flammable fiber, it remains an unparalleled luxury material in the fields of apparel and home textiles. The key is to understand its properties and use it correctly: enjoy its comfort and beauty in a home environment while keeping it away from open flames; and in public and contract projects that require mandatory fire standards, it must be avoided.

Want to understand the differences in flammability, flame-resistant ratings, and LOI (Limiting Oxygen Index) among various fibers? We have compiled a list of related professional articles to help you quickly determine if a material is safe and suitable for use as a flame-resistant fabric, click the link below to view quickly:

A: Cotton is more flammable. Cotton’s LOI (18-20) is much lower than silk’s (24-25). Cotton burns quickly with a large flame, whereas silk burns at a moderate to slow pace.

A: Because the safety requirements for the application are different. Pajamas are a domestic textile, and their flammability is an acceptable risk. Stage curtains are a contract application that must pass mandatory fire standards (like NFPA 701). Natural silk cannot pass these standards and is therefore prohibited.

A: This is determined by its chemical structure. Silk is a protein fiber. When heated, the protein denatures, causing the fiber to curl and shrink rapidly. Simultaneously, the combustion of protein (which contains nitrogen) produces a char odor similar to burnt hair or feathers.

A: Flammability is the bigger safety drawback. Poor light resistance (yellowing) primarily affects aesthetics and lifespan. Flammability, however, is a safety risk related to personal injury and property damage, and it directly leads to silk being banned from all public contract projects.