Fabric Samples: We are pleased to offer complimentary A4-sized fabric samples. Customers are only responsible for the shipping charges.

Customs & Import Duties (U.S.):Due to recent changes in U.S. customs regulations, certain online orders may incur import duties or taxes. These are not included in the item price or shipping cost and are the buyer’s responsibility. Please contact us if you have any questions.

Inherent FR Meta-Aramid (Aramid 1313) Non-woven Insulation Felt – 220°C Heat Resistance

High-performance 300 GSM Inherent FR Meta-Aramid Non-woven Felt (Aramid 1313). Offers stable 220°C heat resistance, high strength, and chemical resistance. Ideal for industrial insulation and PPE Project Supply. Request Bulk Quote.

If you have any questions, please click the button below to chat with us online.

Inherent 220°C Heat Resistance: Meta-Aramid (Aramid 1313) Non-Woven Felt

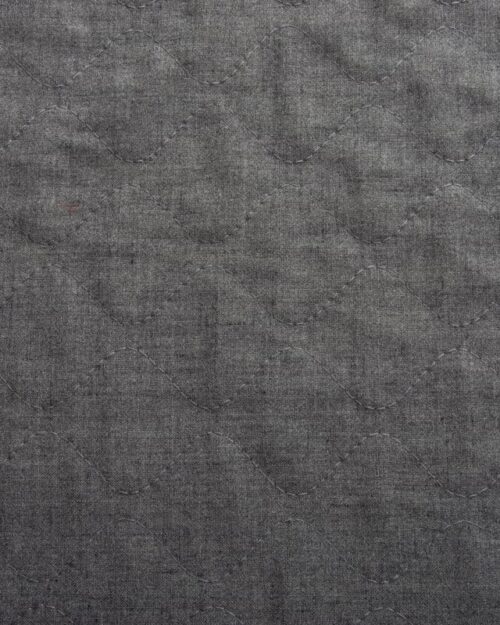

Begoodtex supplies this high-performance Meta-Aramid (Aramid 1313) needle-punched non-woven felt for firefighting, industrial, and medical applications. This soft, off-white felt is made from 100% Meta-Aramid fiber, often called the “fireproof fiber.”

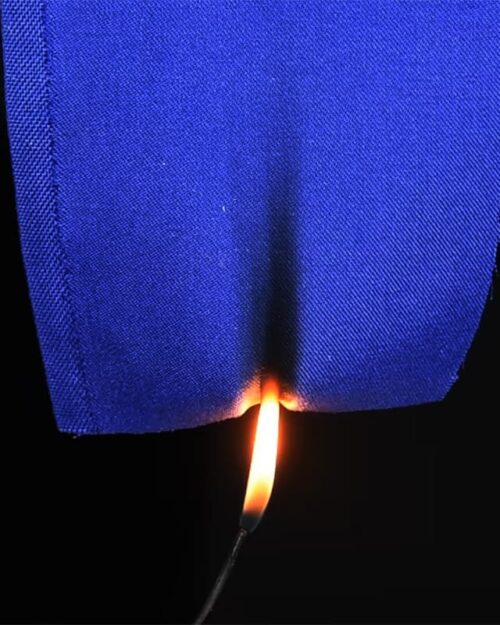

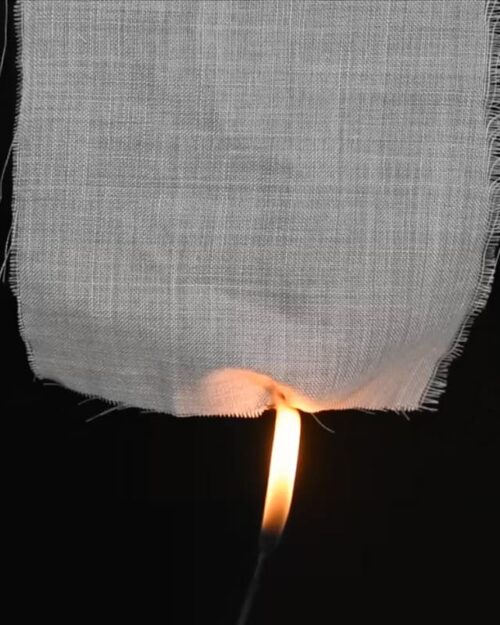

Meta-Aramid is an inherently flame-retardant fiber. It does not burn or support combustion in the air and is self-extinguishing. Its molecular structure provides exceptional thermal stability, allowing long-term use in the -196°C to 220°C range. It exhibits only 1% shrinkage at 250°C and will only char (not melt or drip) when exposed to flame.

Core Advantages and Procurement Commitment

- Inherent FR & Thermal Stability: Rated for 220°C continuous operation with no melt, no drip properties. Decomposes at 560°C.

- High Mechanical Strength: Possesses high tensile strength and superior abrasion resistance (over 100,000 cycles), far exceeding standard fibers.

- Chemical Resistance: Highly tolerant to a wide range of acids and alkalis, making it suitable for corrosive environments.

- Soft & Processable: Features a soft hand, suitable for medical applications and apparel linings, and is easily cut for fabrication.

- Project Supply & Customization: As a professional Technical Textile Factory, we support OEM/ODM customization of various weights (200gsm, 300gsm, 600gsm) and thicknesses (2mm, 3mm, 5mm) to provide a stable, reliable supply for your project.

Ideal Applications

Firefighting garment thermal liners, apparel linings, industrial fire insulation, construction barriers, high-altitude workwear, refinery/steel mill insulation, medical & hygiene fabrics.

Seeking high-performance Inherent FR Meta-Aramid Felt? Contact Begoodtex Technical Textile Manufacturer now to Request Bulk Quote and Get Samples.

FAQ / Common Questions

- Q1: Is this Meta-Aramid (1313) or Para-Aramid (1414)?

A1: This is Aramid 1313 (Meta-Aramid). It is primarily focused on thermal stability (220°C), heat insulation, and chemical resistance, whereas Para-Aramid (1414) is known for extreme strength and cut resistance. - Q2: Why is the “no melt, no drip” feature important?

A2: “No melt, no drip” is a critical safety feature. It means the fabric will not liquefy and drip onto the skin when exposed to intense heat or flame, preventing severe secondary burns. This is essential for high-end PPE. - Q3: Is this felt suitable for apparel linings?

A3: Yes. Meta-Aramid fiber is soft and has excellent textile properties. This non-woven felt is an ideal thermal barrier or insulation layer for high-performance fire protection garments. - Q4: How does it compare to Pre-Oxidized (Pre-ox) Felt?

A4: Both are high-performance Inherent FR felts. Meta-Aramid (1313) generally offers better textile softness, higher abrasion resistance, and better chemical resistance. Pre-ox often has a higher LOI (>45%) and is very cost-effective for pure fire-blocking. - Q5: We need 600gsm at 5mm thickness. Can you customize this?

A5: Absolutely. We are a factory specializing in Project Supply. We can produce this felt in a wide range of weights (200gsm to 600gsm) and thicknesses (2mm, 3mm, 5mm) to meet your exact OEM/ODM order requirements. - Q6: Are you a manufacturer or a trading company?

A6: We are a professional technical textile factory with over 17 years of experience, specializing in OEM/ODM production and international compliance testing for FR and heat-resistant fabrics.

I. Fabric Packaging

The fabric packaging solution is customizable to meet your specific needs. We consistently use high-quality packaging materials to ensure the protection of the fabric.

The core of our packaging is a sturdy paper tube. It has a thickness of 7mm, an outer diameter of 9cm, and an inner diameter of 7.6cm. This design provides excellent support, preventing the fabric from being crushed or deformed during transit.

For the outer layer, each roll is enclosed in a transparent PE tube bag. This bag has a minimum thickness of 12.5 silk (0.125mm) which makes it highly durable and resistant to tearing. The transparent material allows for easy inspection of the fabric without opening the package, while its properties effectively protect the contents from moisture and dust.

To secure the packaging and for brand identification, the two ends of each roll are sealed with custom-printed adhesive tape. This tape not only firmly seals the PE bag but can also be customized with your brand logo, product information, or other specified designs.

II. Finished Packaging

Our finished products are not only carefully manufactured but also meticulously packaged under strict quality standards. Each item—whether home textiles, bedding, event supplies, medical supplies, clothing, or industrial fabrics—is packed in a way that ensures maximum protection, cleanliness, and presentation value.

We use durable cartons, sealed polybags, and protective inner packaging to safeguard fabrics against moisture, dust, and damage during long-distance transportation. For retail-ready products, we provide customized color boxes, printed labels, and barcode systems, ensuring a professional appearance and easy inventory management.

All cartons are clearly marked with product information and “Made in China” for export compliance. Our packaging team follows international shipping standards, making sure goods are stackable, easy to load/unload, and suitable for sea, air, or land transportation.

This comprehensive approach guarantees that when our products arrive at your destination, they are not only intact and ready for use, but also presented in a way that enhances your brand image and customer experience.

III. Protective Packaging

For high-end fabrics and bulk shipments, we adopt reinforced protective packaging solutions to guarantee the integrity of every roll. Each fabric roll is first individually wrapped in moisture-proof plastic film and securely fastened to prevent dust, humidity, or contamination. After that, the rolls are carefully placed into strong wooden crates for maximum protection during long-distance transportation.

Our wooden crates are manufactured with high-strength materials, reinforced with nails and steel bands, and designed to withstand heavy stacking, impact, and vibrations during shipping. This ensures that even delicate or premium fabrics arrive at their destination in perfect condition without deformation or damage.

In addition, we follow international export packaging standards, making our wooden crates suitable for sea freight, air freight, and land transport. Each crate is clearly labeled with product details and handling instructions, ensuring smooth customs clearance and efficient logistics management.

By adopting this level of protective packaging, we provide our clients with peace of mind, knowing that their valuable goods will be delivered safely, securely, and ready for immediate use upon arrival.

IV. Goods Shipping

When it comes to shipping, we implement strict loading procedures to ensure both safety and efficiency. Goods are carefully arranged and stacked in containers, with optimized space utilization to reduce transportation costs while maintaining stability throughout the journey.

Every carton, roll, or crate is placed in an orderly and secure manner, preventing shifting or collapsing during long-distance transit. When necessary, we apply reinforced strapping, stretch film, pallets, and protective cushioning materials to further stabilize the cargo and protect against vibration, friction, or impact.

Our experienced logistics team follows international shipping standards, coordinating with major freight carriers to guarantee smooth container loading, timely departure, and safe delivery. Containers are also regularly inspected and reinforced to ensure they are clean, dry, and free from potential hazards such as rust or water leakage.

This meticulous process ensures that all products—whether fabrics, textiles, or finished goods—arrive at their destination on time, intact, and in perfect condition, giving our clients confidence in every shipment.

| FR Standard | ASTM F1506, EN 469, EN ISO 11611, EN ISO 11612, EN ISO 14116, FAR 25.853, NFPA 2112 |

|---|---|

| Width | |

| Weight | 200 g/m² |

| Material | |

| Application |

What does BEGOODTEX produce?

We produce IFR fabrics such as premiere, spandex, dimout, cubicle curtain, pajama, velour, sheeting, and cellular blanket fabrics.

What is your Minimum Order Quantity (MOQ)?

MOQ varies by fabric type. We support flexible MOQs for both small and large projects.

What are your shipping methods for wide-width fabrics?

Fabrics can be shipped as 320cm rolls wrapped in bubble wrap. We can also fold 280cm-wide fabric to 140cm and roll it to reduce volume. Tube packing is available upon request.

What is your pricing currency and delivery term?

Prices are quoted in USD or RMB, under FOB Shanghai/Ningbo terms.

How long is your quotation valid?

Quotations are valid for 60 days.

What is your lead time?

Typically 30–35 days after deposit, depending on quantity and customization.

What are your payment terms?

30% deposit before production, 70% balance before shipment. We accept T/T, L/C, PayPal, Western Union, and Alibaba Trade Assurance.

Are your fabrics made with inherently flame-retardant yarns?

Yes. The flame-retardant properties are embedded in the fibers, ensuring long-lasting performance even after 50+ washes.

For more questions, please visit the FAQ section.

Related products

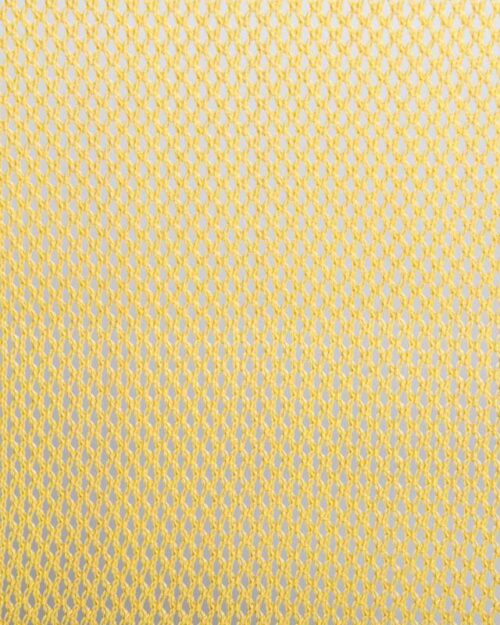

High-Performance Fireproof Aramid Mesh Fabric | 170cm | Firefighting Suit Lining

Inherent FR Aramid 1313/1414 Blend Fabric for Arc Flash & Firefighter Suits

Dual-Layer Aramid Viscose Blended FR Fabric Quilted Felt Fireproof Fabric

Wholesale Aramid Mesh Fabric | 150cm 260g/m² | NFPA 2112 FR Textile Factory

Lightweight Inherent FR Meta-Aramid (Aramid 1313) Woven Fabric – 60 GSM

Wholesale Lightweight Aramid Mesh Fabric Inherent FR | Protective Clothing

Aramid PTFE Laminated Fireproof & Breathable Fabric EN469 Certified

Reviews

There are no reviews yet.